Applied arrange: In Iron ore, manganese, chromium, titanium, vanadium , ungsten and tin ore processing.

General introduction:

Gravity separation process is an ore separation method according to the mineral ore density difference. It plays an important role in modern processing methods. Gravity separation is also a kind of more economic beneficiation process.

Gravuty separation process needs gravity equipment including classifier, jigger, shaking table and spiral chute, and gravity media such as air or water; its main advantages lie in simple structure and economical cost.

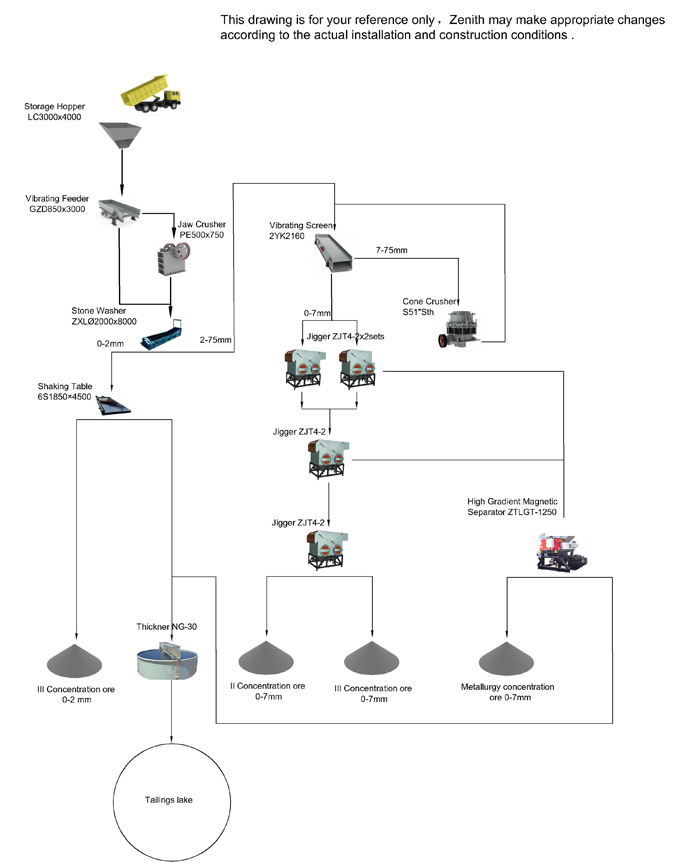

Detailed process flow:

Water desliming→ water classification→shaking table separation

Water desliming : Using waterflow to segregate agglomerate or fine clayor bonding with quartz, and remove the clay.

water classification: As minerals of different sizes have different settling velocity in waterflow , this can divide different fractions according to requirement.

shaking table separation: Iron and dense particles' sedimentation in water is faster; under the joint effect of horizontal and vertical flow, low density quartz grain would get separated from dense minerals.

Technical features:

1.Gravity concentration equipments are simple and stable, easy to operate and economical. the technology is also relatively mature.

2.Expensive reagents are no need in gravity separation processing ,discharged tailings cause little pollution.

3.Discarding the blocky rock mass and coarse tailings and separate coarse disseminated-grain low-magnetic minerals;

4. Coordinate with other separation methods to recycle fine disseminated-grain low-magnetic minerals.

5.For coarse disseminated grain minerals, gravity separation can get good separation performance. This could produce coarse concentrates or mixed concentrates, as well as the final concentrates.