Floatation is a main method to separate the ores by the different natures of wetting by water. The hydrophobic mineral will be gathered on the bubbles and floats on the surface. However, the hydrophilic minerals will stay in the water.

Applies for the following ores:

Gold ore, silver ore, galena, sphalerite, copper ore, molybdenum ore, pentlandite and other sulphide minerals.

Malachite, cerussite, smithsonite, hematite, cassiterite, wolframite, ilmenite, rare-earth metal and other oxide minerals.

Graphite, sulphur, diamond, quartz, mica, feldspar and other nonmetallic minerals. silicate mineral.

Fluorite, apatite, barite and other nonmetallic saline minerals.

Sylvite, rock salt and other soluble minerals.

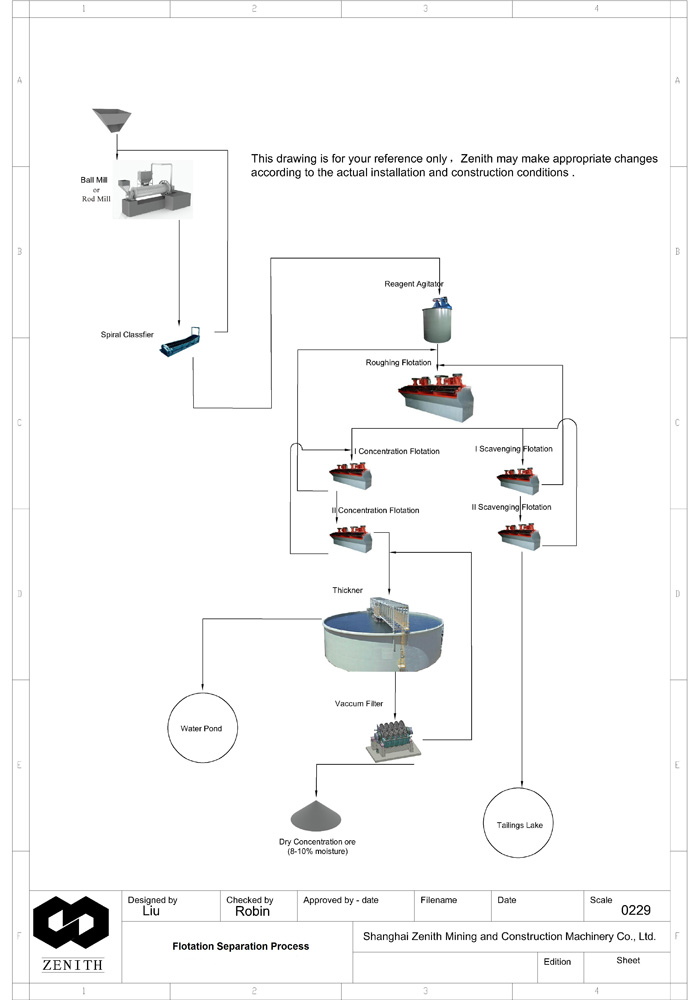

Technical process:

1. Preparation work:

Grinding, classification, mixing, adding reagents, agitating, etc.. The aim is to get the proper pulp with suitable size and density for further process.

2. Agitating, mixing air and the mineralization of bubbles:

Air is sucked or pressed into the pulp, are mixing with floatation reagents, hydrophobic mineral particles will be adhered to the bubbles which are stable with suitable size. And hydrophilic mineral particles will stay in the pulp.

3. To get the concentrate

Hydrophobic minerals will be adhered to the bubbles and float to the pulp surface, and then being scraped by the scrapers of floatation machines and become the concentrate, the left pulp is tailings.

Floatation machines

1. SF/BF Floatation Machine

This machine can imbibe the air and ore pulp spontaneously by the zone of negative pressure in the lower part of floatation machine.

2. XCF Floatation Machine

The air is compressed by the pipeline. The impellers are mainly for keeping the pulp suspending.

3. Floatation Cell

There are no impellers device, the compressed air are for agitating.

Effect factors to floatation

1. Grinding size

2. The density of pulp

3. The reagent

4. Agitating

5. Temperature of pulp.

6. Flotation time, which is determined by the dressing test.