The Mn element is very important in the metallurgy and other fields. 90% of it is used in the steel industry for improving hardness, strength, abrasive resistance, toughness and harden ability of the steel.

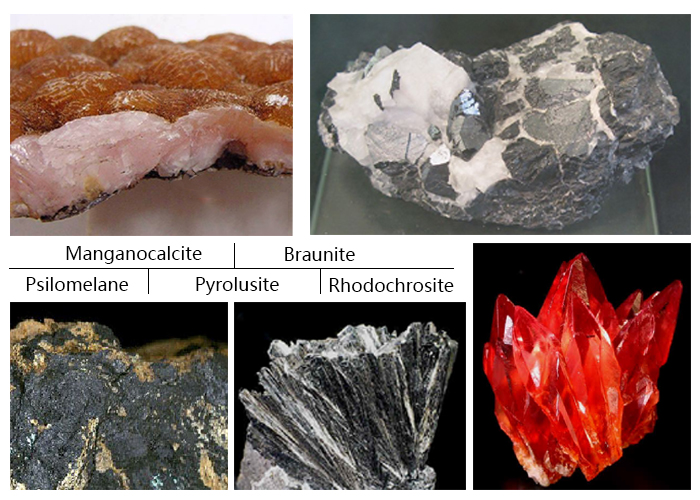

Types of Manganese ore

Mn is always occurrence in the oxidate, hydroxide and carbonate. All the manganese ore can be classified into the manganese carbonate ore and manganese oxide ore. The manganese carbonate contain the magnesite, Calcium magnesite, tetalite and so on. The manganese oxide ore always includes the pyrolusite, psilomelane and braunite. Please see the table as below to help you know more about it.

| Name | Content | Density (g/cm3) |

Colour | Theoretical Cu grade | Cut-off grade | Product grade | M Hardness |

| Rhodochrosite | MnCO3 | 3.3~3.7 | Pink or White | 47.82% | ≥10% | ≥15% | 3.5~4..6 |

| Manganocalcite | (Ca, Mn) CO3 |

2.7~3.8 | Pink or White | 46.65% | ≥10% | ≥15% | 3.5~4.5 |

| Psilomelane | mMnO·MnO2 ·nH2O |

3.7~4.7 | Dark or Grey | -- | ≥10% | ≥15% | 4~6 |

| Pyrolusite | MnO2 | 4.3~5 | Ocher or Brown | 63.19% | ≥10% | ≥15% | 2~5 |

| Braunite | Mn2O3 | 4.7~5 | Gray Black | 69.90% | ≥10% | ≥15% | 6~6.5 |

The Solution for processing manganese ore

According to the raw material is Manganese carbonate ore or manganese oxide, there is different beneficiation method for processing. But the final design should be based on the dressing report of the raw material. And the dressing report should be done by the professional institute. Here are some general solution for Manganese carbonate ore or manganese oxide.

Manganese carbonate ore:

1. High intensity magnetic separation technology;

2. Flotation technology

Manganese Oxide:

1. Gravity separation;

2. Washing + Gravity Separation

3. Washing +Gravity Separation+ High intensity magnetic Separation

Common equipment

PEW Jaw Crusher, HP Cone Crusher, HST Cone Crusher, S series cone crusher, vibrating screen

Ball mill

Hydro cyclone, spiral classifier

ZGT series high gradient magnetic separator

CT series wet magnetic separator

JT series jigger

6S series shaking table

LL series spiral chute