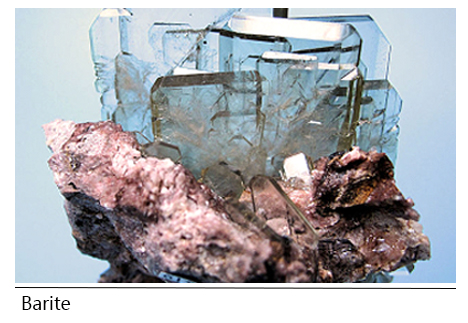

Introduction of Barite:

Baryte, or barite, (BaSO4) is a mineral consisting of barium sulfate.The baryte group consists of baryte, celestine, anglesite and anhydrite. Baryte itself is generally white or colorless, and is the main source of barium. Its specific gravity is 4.3-5 and the mosh hardness is 3-3.5.

Barite occurs in a large number of depositional environments, and is deposited through a large number of processes including biogenic, hydrothermal, and evaporation, among others.[1] Baryte commonly occurs in lead-zinc veins in limestones, in hot spring deposits, and with hematite ore. It is often associated with the minerals anglesite and celestine

Main industrial index:

Cutoff grade: (BaSO4)10%

Industrial grade: (BaSO4)30%

Exploration thickness: original deposit 0.25meter, weathering clay deposit 1meter.

Barite product has different specification and quality request based on different use. In petroleum Drilling field, the passing rate of 200 mesh of barite is over 97% and 300 mesh is over 95%. In chemical industry, the product has three grade with percentage of BaSo4 is 85%, 90%, 95% and other element contains could be different. In paint, rubber, glass industry, the final size and contains of BaSO4 should be 90- 98% and some harmful elements are limited strictly.

The Solution for processing barite ore

For getting the qualified barite ore, the raw ore should be concentrated to improve the grade. The barite ore always use the processing way as below:

1. Gravity separation;

2. Washing + Gravity Separation

3. Washing +Gravity Separation+ High intensity magnetic Separation

Common equipment

PEW Jaw Crusher, HP Cone Crusher, HST Cone Crusher, S series cone crusher, vibrating screen

Ball mill

Hydro cyclone, spiral classifier

ZGT series high gradient magnetic separator

CT series wet magnetic separator

JT series jigger

JT series jigger

6S series shaking table

LL series spiral chute

SF Series Flotation Cells

BF Series Flotation Cells

XCF-KYF Series Flotation Cells