To minimize the generation of powder when crushing limestone, consider the following strategies:

Moisture Control: Maintain optimal moisture levels in the limestone. Pre-wetting the material can help reduce dust.

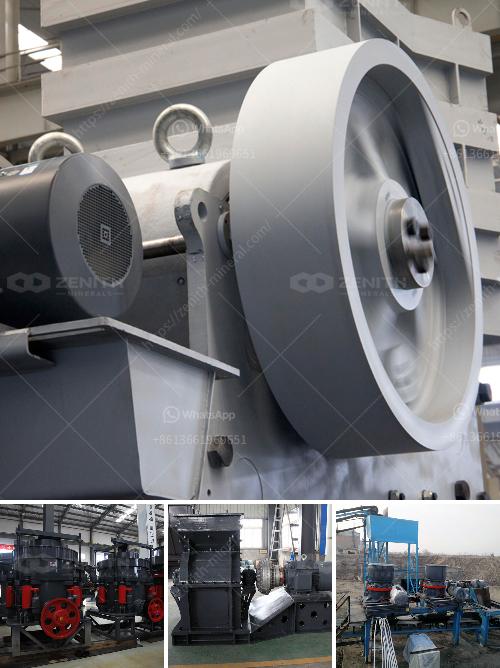

Equipment Choice: Use equipment designed to minimize dust. Jaw crushers and cone crushers are often preferred for their efficiency and lower dust output compared to impact crushers.

Feed Rate: Adjust the feed rate to ensure the crusher isn't overloaded, as overloading can lead to excess dust production.

Blasting: Optimize blasting techniques to produce coarser material that requires less crushing and generates less dust.

Screening: Implement screening techniques to separate fines at an early stage, reducing the amount of material that needs crushing.

Choke Feeding: Maintain a consistently full chamber for crushers, as choke feeding can reduce the amount of fines produced.

Dust Suppression Systems: Install dust suppression or extraction systems, such as water sprays, fog systems, or dust collectors to capture dust at the source.

Material Handling: Practice gentle material handling techniques to minimize dust generation.

By combining these approaches, you can effectively reduce the amount of powder produced during the limestone crushing process.