Screening 200-mesh quartz using a rotary sieve involves several steps to ensure effective material separation. Here’s a step-by-step guide:

Equipment and Preparation

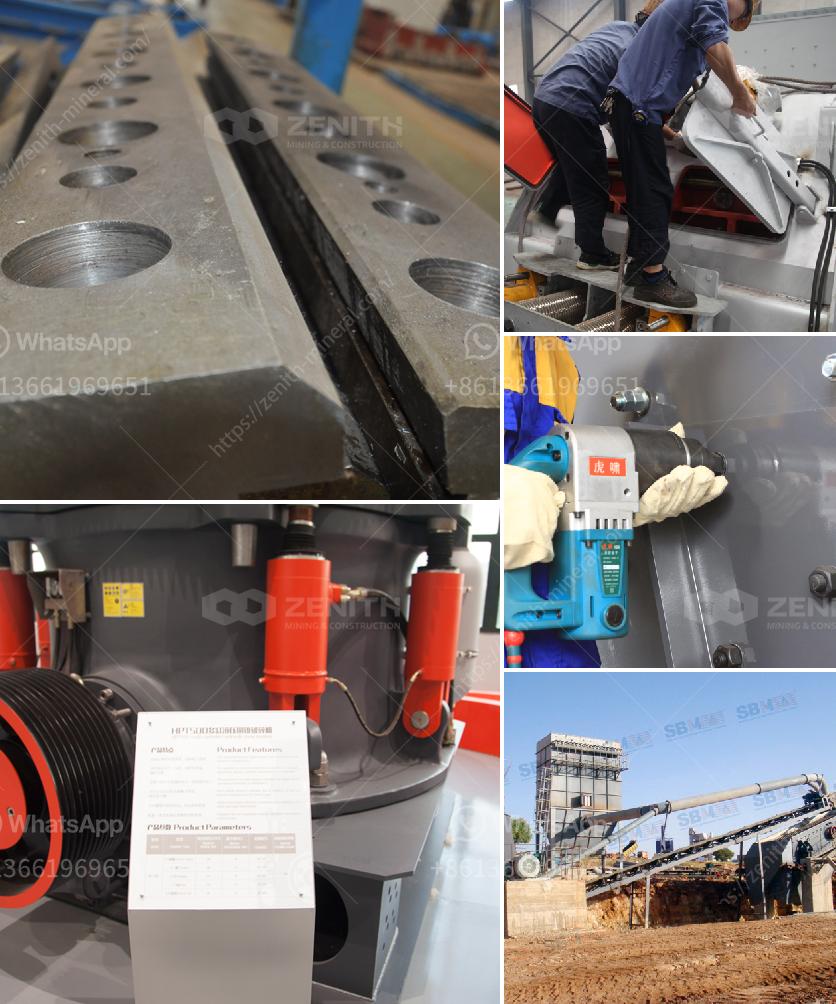

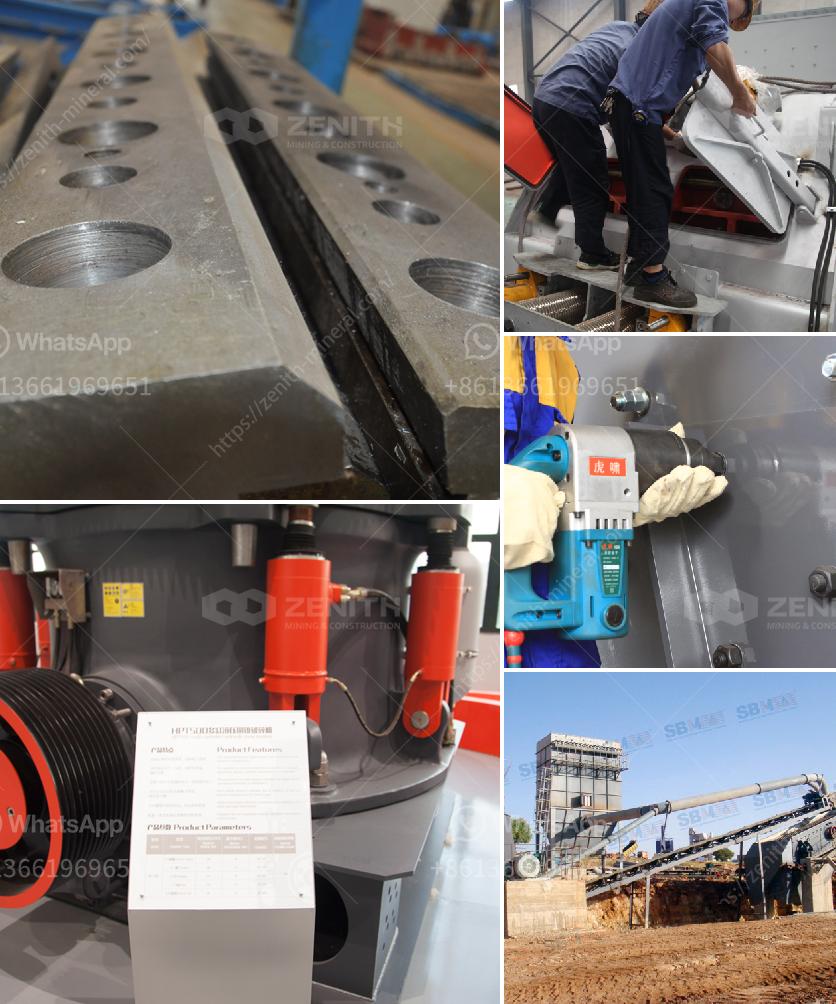

- Rotary Sieve (Rotary Sifter): Ensure you have a rotary sieve suitable for the particle size you are working with. The sieve should be equipped with a 200-mesh screen.

- Quartz Material: The raw quartz should be prepared and free from large debris.

- Feed Hopper: A hopper to feed the quartz into the rotary sieve consistently.

Steps

-

Setup:

- Place the rotary sieve on a stable surface.

- Connect it to a power source if it is electrically operated.

- Ensure the 200-mesh screen is securely installed within the machine.

-

Feeding the Material:

- Pour the prepared quartz into the feed hopper.

- Start the machine, making sure the rotary sieve is running at the recommended speed for optimal screening.

- Control the feed rate to avoid overloading the sieve, which can lead to ineffective screening.

-

Screening Process:

- The rotary motion will facilitate the separation of quartz particles. The finer particles (200-mesh) will pass through the screen, while larger particles will be moved to an exit port.

- Collect the screened quartz in a container placed below the machine.

-

Check Results:

- Regularly check the throughput to ensure the mesh isn’t clogged.

- Assess the screened material to verify that it meets your quality requirements.

- Adjust feed rate or rotary speed if screening efficiency needs improvement.

-

Maintenance and Cleaning:

- After completing the screening, turn off and unplug the machine.

- Clean the mesh screen and other parts of the rotary sieve to prevent contamination and maintain efficiency for future use.

-

Safety Considerations:

- Wear appropriate protective gear, such as gloves and goggles, to avoid exposure to dust.

- Ensure that the work area is well-ventilated to prevent inhalation of fine quartz particles.

Following these steps should help you effectively screen 200-mesh quartz through a rotary sieve.