To determine if the head of a cone crusher has come up, you need to monitor several indicators and parameters. Here are some detailed steps and methods to help you identify this condition:

-

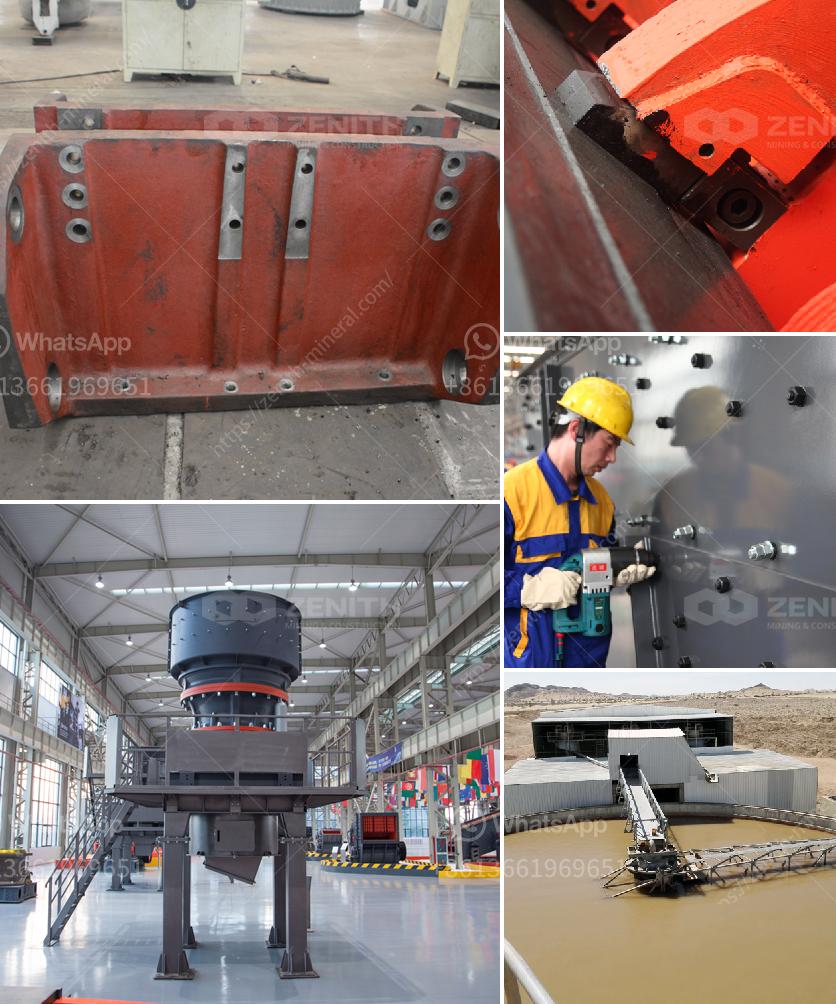

Visual Inspection:

- Physical Observation: Regularly inspect the crusher during operation. If the head has come up, you might notice a visible gap between the head and the bowl liner.

- Wear Patterns: Check for unusual wear patterns on the liners. If the head has come up, the wear might be uneven or more pronounced in certain areas.

-

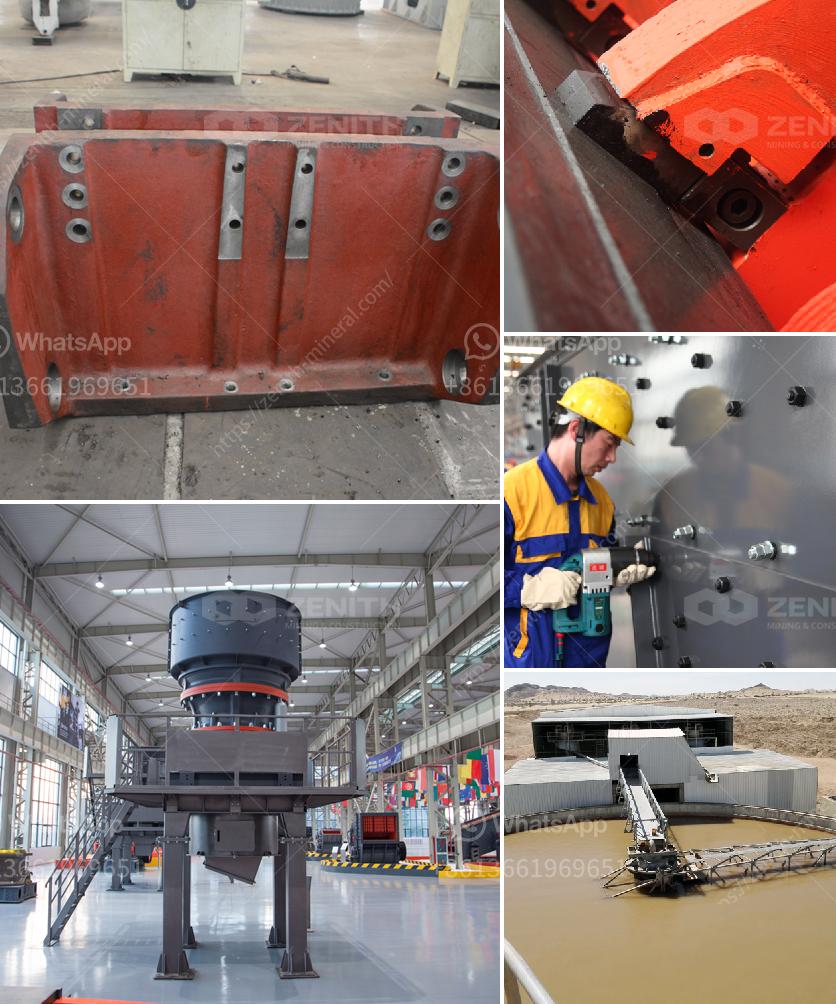

Monitoring Systems:

- Hydraulic Pressure: Cone crushers often have hydraulic systems to adjust the position of the head. Monitor the hydraulic pressure; a significant change might indicate that the head has moved.

- Position Sensors: Some modern cone crushers are equipped with position sensors that provide real-time data on the head's position. Check the readings from these sensors to see if the head has come up.

-

Operational Parameters:

- Power Draw: An increase in power draw can indicate that the head has come up, as the crusher might be working harder to crush the material.

- Throughput: A decrease in throughput can also be a sign, as the crusher might not be operating at its optimal efficiency.

-

Auditory Cues:

- Unusual Noises: Listen for any unusual noises during operation. A change in the sound of the crusher can indicate that the head has come up and is not crushing material as intended.

-

Maintenance Records:

- Historical Data: Review maintenance records and historical data. If the head has come up before, there might be patterns or recurring issues that can help you identify the problem early.

-

Vibration Analysis:

- Vibration Monitoring: Use vibration analysis tools to monitor the crusher. An increase in vibration levels can indicate that the head has come up and is causing imbalances in the crusher.

By combining these methods, you can effectively determine if the head of a cone crusher has come up and take appropriate action to address the issue. Regular monitoring and maintenance are key to ensuring the efficient and safe operation of the crusher.