Crushing aggregates involves several steps and the use of specific machinery to break down large rocks into smaller particles suitable for construction and other uses. Here's a general overview of the process:

1. Mining and Quarrying:

- Aggregates are typically mined from quarries or sites with natural rock formations.

- Blasting or drilling is often used to break large rocks into more manageable sizes.

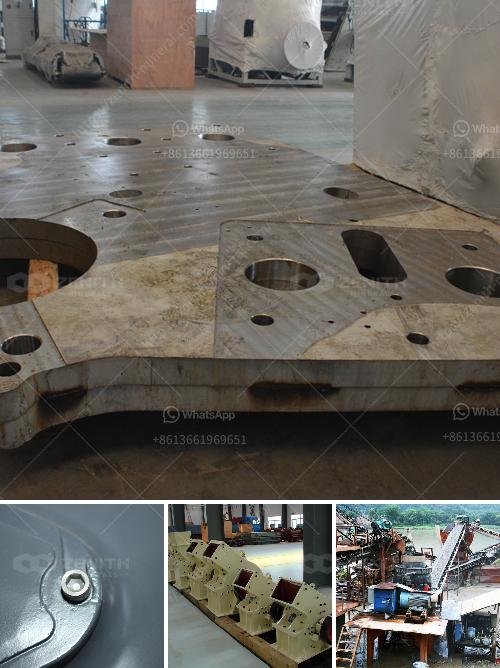

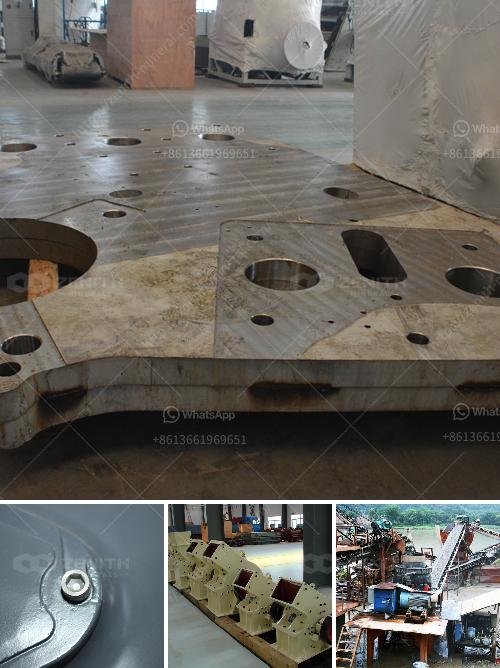

2. Primary Crushing:

- Equipment: Jaw crushers or gyratory crushers.

- Process: Large rocks from the quarry are fed into the crusher, which breaks them into smaller pieces (approximately less than 200 mm in size).

3. Secondary Crushing:

- Equipment: Cone crushers, impact crushers, or hammer mills.

- Process: The output from the primary crusher is fed into a secondary crusher for further reduction. This step produces aggregates that are more uniform in size.

4. Screening:

- Equipment: Vibrating screens or rotary screens.

- Process: After secondary crushing, the material is screened to separate fine particles from larger ones. The oversized material is often returned to the crusher for further processing.

5. Tertiary Crushing (if needed):

- Equipment: Specialized crushers like VSI (Vertical Shaft Impact) crushers.

- Process: Further refinement of the aggregate size and shape to meet specific requirements for certain projects.

6. Washing (optional):

- Equipment: Wash screens or log washers.

- Process: To remove dirt, clay, and other impurities from the aggregate.

7. Stockpiling:

- Process: Finally, the processed aggregates are stockpiled and ready for transportation or use.

Safety and Environmental Considerations:

- Dust Suppression: Use of water sprays or dust collection systems to minimize dust.

- Noise Control: Implementing noise reduction measures to comply with local regulations.

- Environmental Impact: Ensuring responsible mining practices to reduce the ecological footprint.

This is a high-level overview, and each step can have multiple variations depending on the type of material, desired end-product, and specific requirements of the project. Always consult with industry professionals and adhere to local regulations when setting up and operating crushing machinery.