Controlling the feed size to a ball mill is crucial for optimizing its performance and efficiency. Here are some key strategies to manage the feed size effectively:

-

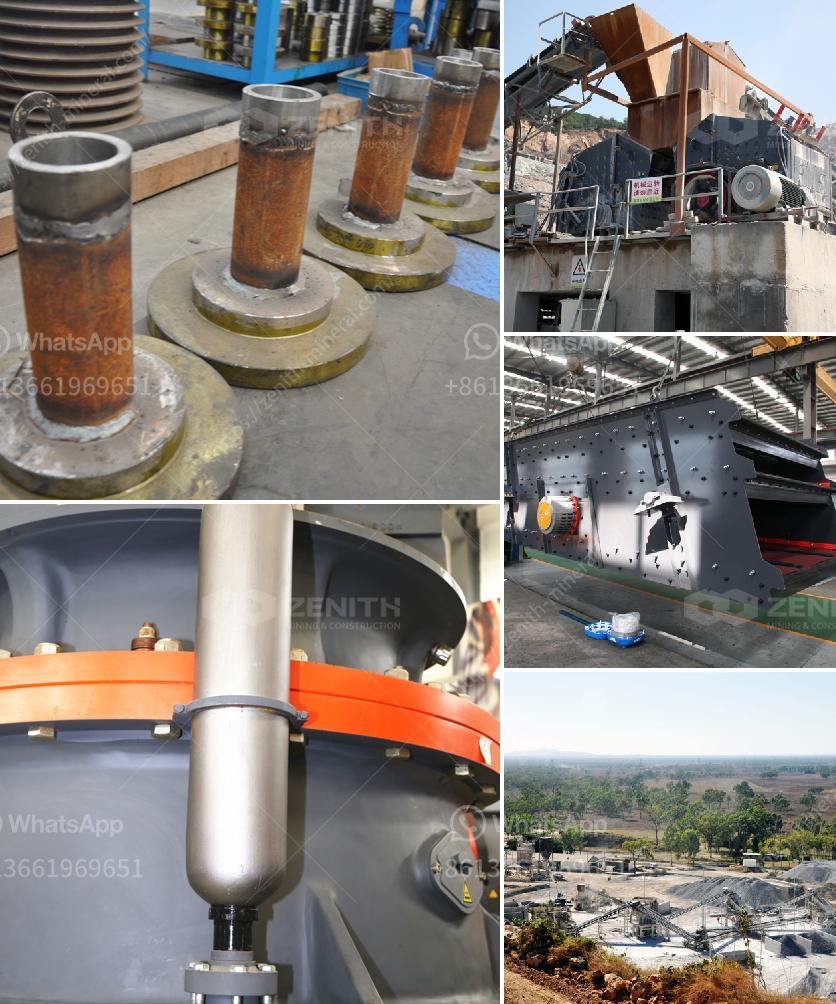

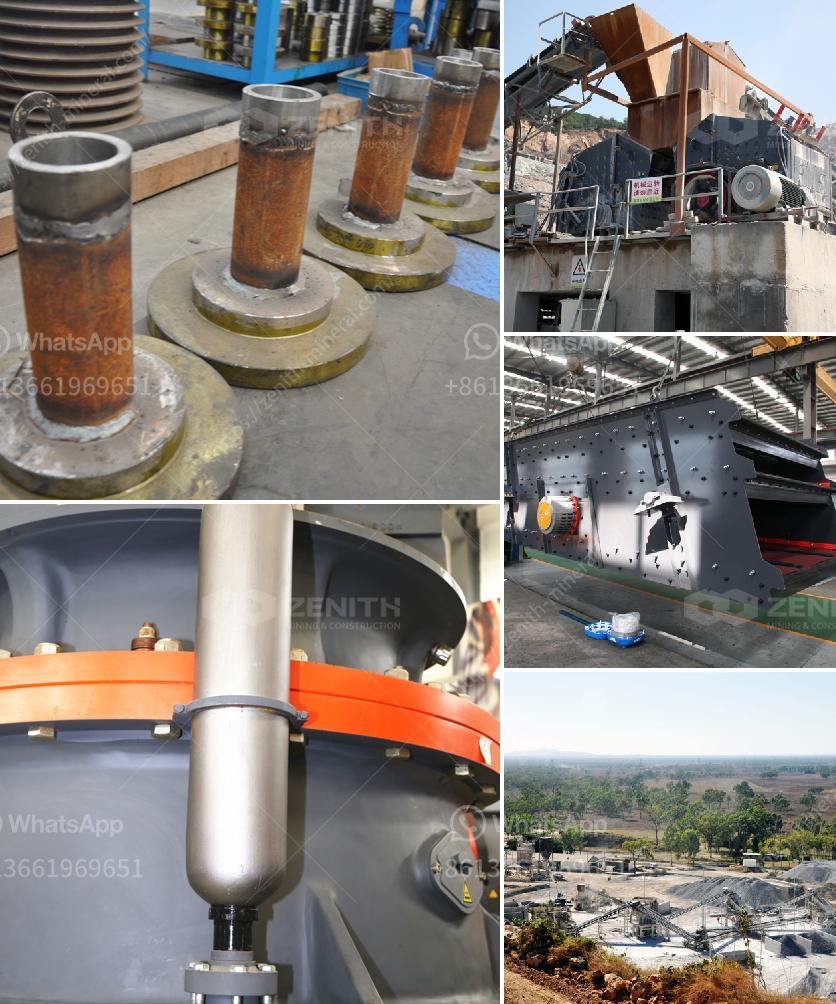

Screening and Pre-Processing:

- Pre-screening: Use screens to separate fines before feeding material into the ball mill. This reduces the load on the mill and ensures that only material of the desired size range is processed.

- Crushing: Employ crushers to reduce the primary ore size to a more manageable size before it enters the ball mill.

-

Feed Adjustment:

- Uniform Feeding: Ensure a consistent and uniform feed rate using a feeding mechanism like a vibrating feeder or conveyor belt. This prevents overloading and ensures that the mill operates smoothly.

- Control Valve: Use a feed control valve to adjust the feed rate dynamically in response to mill performance and throughput needs.

-

Grading Machine Usage:

- Classifiers: Implement classifiers such as cyclones or hydrocyclones to segregate particles by size. Fine particles can be directed back to the mill or processed separately, while oversize particles are recirculated for further grinding.

-

Monitoring and Automation:

- Real-time Monitoring: Use sensors to continuously monitor the particle size distribution and feed rate, adjusting the mill’s operation parameters as needed.

- Automated Systems: Integrate an automated control system that utilizes feedback from monitoring instruments to make precise adjustments to feed size and rate.

-

Proper Maintenance:

- Regular Inspection: Periodically check the condition of crushing and screening equipment to ensure they are functioning correctly and efficiently.

- Maintenance Schedule: Adhere to a strict maintenance schedule for all pre-processing equipment to avoid unexpected breakdowns that could affect feed size.

-

Material Properties:

- Ore Characteristics: Understand the properties of the material being processed (e.g., hardness, moisture content) to tailor the crushing and screening setup accordingly.

- Adjustable Settings: Modify crusher settings and screen apertures based on the ore characteristics to achieve the desired feed size.

By implementing these strategies, you can effectively control the feed size to your ball mill, improving overall grinding efficiency and optimizing production outcomes.