Extracting iron efficiently from silica involves several steps and techniques, often depending on the specifics of the ore and desired purity of the extracted iron. Here are some common methods:

-

Magnetic Separation:

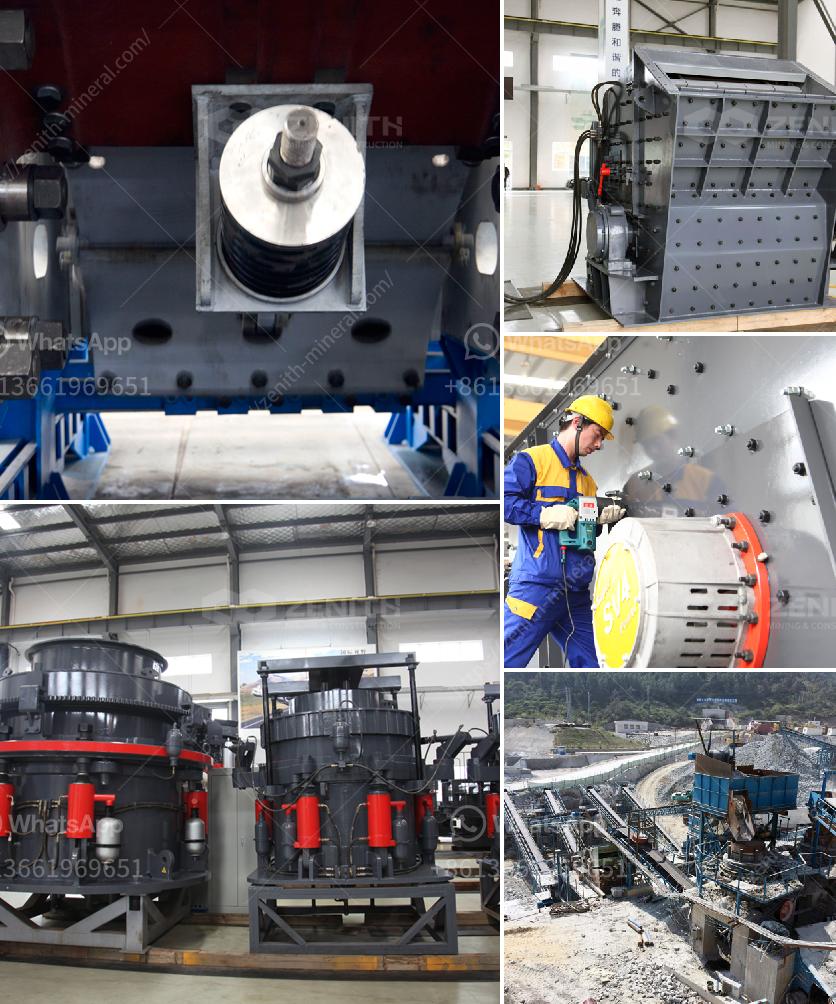

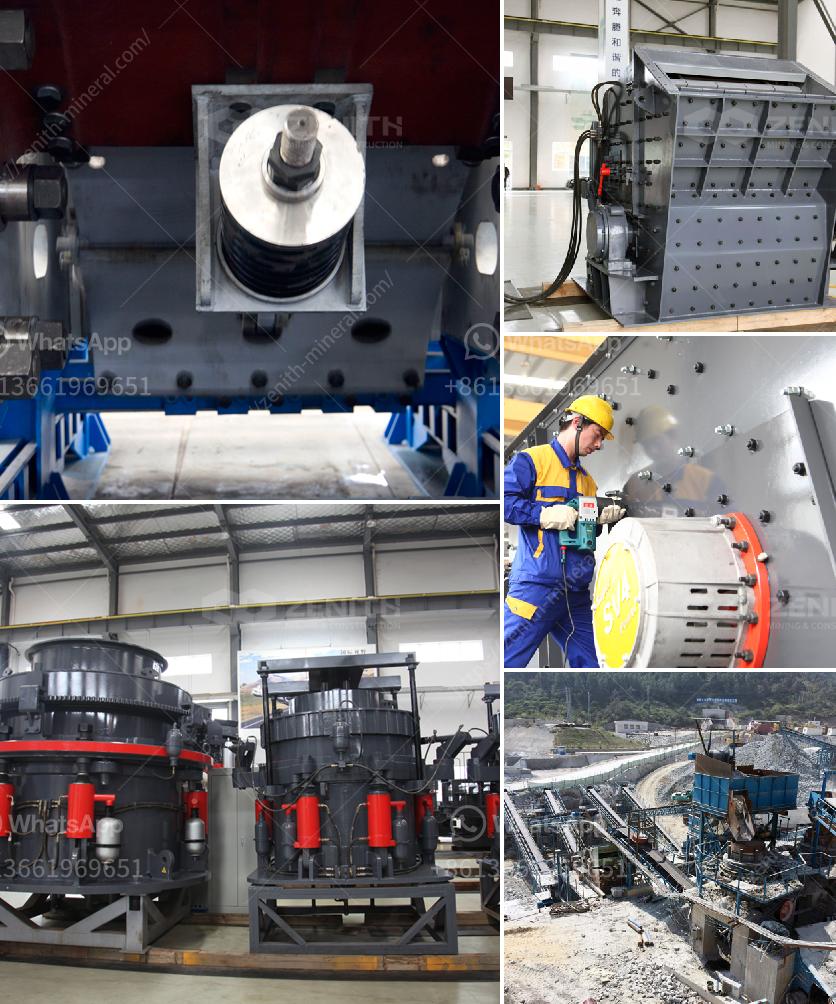

- Crushing and Grinding: The ore must first be crushed and ground to liberate the iron-bearing minerals from the silica.

- Magnetic Separator: Use a magnetic separator to separate iron ore from the non-magnetic silica.

-

Froth Flotation:

- Reagents: Add reagents that selectively attach to iron particles, making them hydrophobic (water-repellent).

- Floatation Cells: Agitate the slurry in flotation cells to create bubbles; the iron ore particles stick to the bubbles and float to the surface, where they can be skimmed off.

-

Chemical Leaching:

- Acids or Alkalies: Use an acid or alkaline solution to dissolve silica, leaving behind the iron.

- Washing: Thoroughly wash the remaining material to separate the iron from the dissolved silica products.

-

Physical Methods:

- Gravity Separation: This method can be useful if there is a significant density difference between the iron ore and the silica. Techniques like jigging or using shaking tables can help concentrate the iron.

-

Hydrometallurgical Methods:

- Selective Dissolution: Employ specific solvents to dissolve silica selectively, leaving the iron behind, or vice versa.

Each of these methods can vary in efficiency, cost, and environmental impact, so the choice of method may depend on the specific characteristics of the ore and the context of the mining operation. Combining several methods is also common to achieve optimal results.