When dealing with granite's high hardness and abrasiveness, it's crucial to use crushers specifically designed to handle such tough materials. Here are some crushers that are best suited for granite:

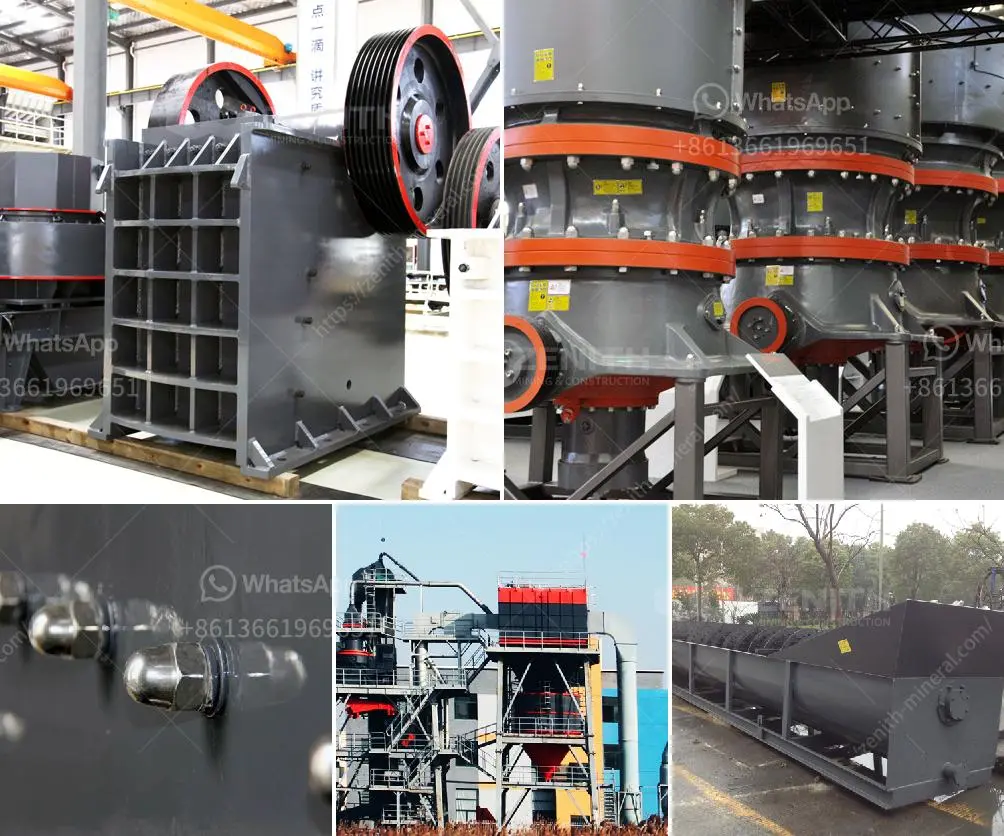

Jaw Crushers: Jaw crushers are commonly used as primary crushers for granite because of their ability to handle large pieces of material. They are robust, durable, and capable of withstanding the compressive stresses of granite.

Cone Crushers: These are often used as secondary or tertiary crushers. Cone crushers can handle the high compressive strength of granite and provide a good reduction ratio. They are effective in producing well-shaped aggregates.

Impact Crushers: While impact crushers are generally used for less abrasive rocks, some models, like the horizontal shaft impactors (HSI), can be equipped with durable wear parts and may be used effectively with granite, provided the abrasiveness is moderated.

Gyratory Crushers: Similar to jaw crushers, they are used in primary crushing stages and are suitable for processing large quantities of granite due to their high capacity.

For optimal performance and longevity of the equipment, it's crucial to ensure that crushers are regularly maintained and equipped with high-quality wear parts, such as manganese steel liners, that can withstand the abrasiveness of granite. Additionally, consulting with crusher manufacturers to select the most suitable model and settings for your specific requirements can be beneficial.