Converting crusher motor power to tons per hour is not straightforward because it depends on several variables, including the type of material being processed, its hardness, and the efficiency of the crusher. However, there are some general steps and considerations that can help estimate this conversion:

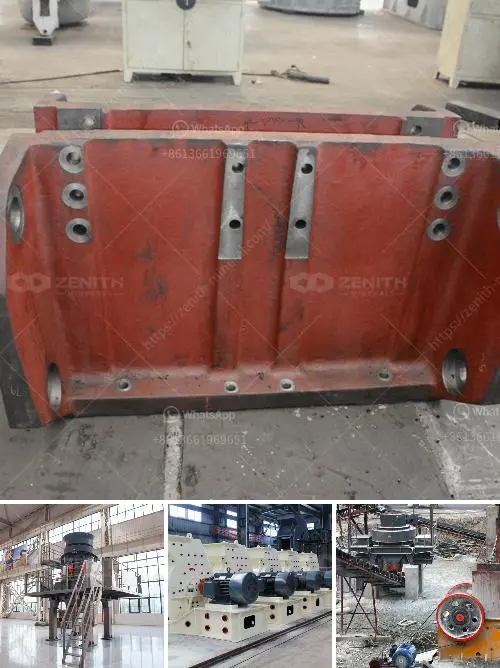

Understand the Crusher Type: Different types of crushers (jaw, impact, cone, etc.) have different efficiencies and capabilities. It's essential to know the specific type you're dealing with.

Material Characteristics: The size, hardness, moisture content, and other properties of the material being crushed can significantly impact the conversion rate. Harder materials require more power to crush, which may reduce the tons per hour output.

Crusher Efficiency: Assess the efficiency of the crusher. Older or improperly maintained machines might not operate at their optimal capacity, which would affect the conversion.

Motor Power Rating: Identify the motor power in kilowatts (kW) or horsepower (HP). This is the starting point for the conversion.

Performance Curves: Manufacturers often provide performance curves or charts that show the expected output in tons per hour at different power levels. Refer to these resources if available.

General Estimation Formula: While there is no universal formula, an empirical approach often used is: \[ \text{Tons per Hour} = \frac{\text{Motor power (kW/HP)} \times \text{Crusher efficiency} \times C}{\text{Material hardness factor}} \] Where ( C ) is a constant derived from empirical studies of similar crushers.

Consult Equipment Manuals: Different manufacturers may provide specific guidelines or conversion factors based on their machine specifications. Referring to these manuals will provide more accurate estimates.

Professional Guidance: Sometimes, the best approach is to consult with engineers or professionals from the crusher manufacturer to get precise calculations tailored to your specific application.

Remember, any estimation should take into account operational data and real-world experience, as theoretical calculations can differ from practical results.