A vibrating feeder is a piece of industrial equipment designed to transport bulk materials, such as coal, from one location to another in a controlled manner. The primary function of a vibrating feeder is to ensure a consistent and uniform flow of material, which is crucial for various processes in industries like mining, construction, and manufacturing. Here's a detailed explanation of how a vibrating feeder for coal works:

Hopper: This is the container where the coal is initially loaded. The hopper holds the bulk material and releases it onto the feeder tray.

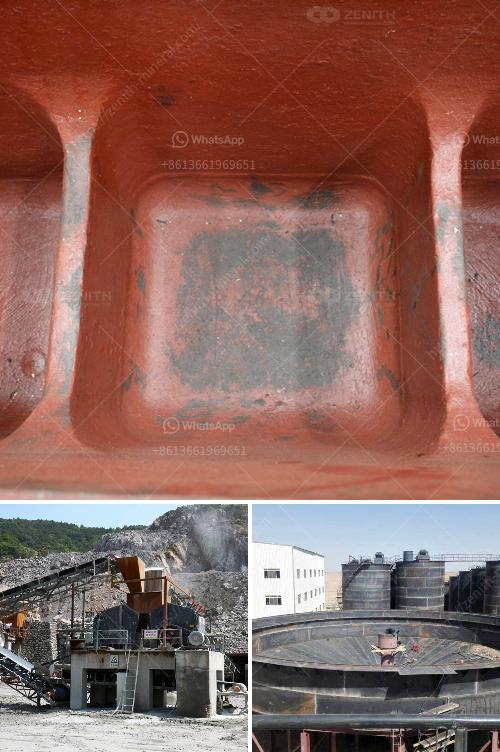

Feeder Tray: Also known as the trough, this is the surface on which the coal is transported. The tray is typically made of durable materials to withstand the abrasive nature of coal.

Vibratory Motors: These are the primary components that generate the vibrations. They are usually electric motors with unbalanced weights attached to their shafts. When the motors run, the unbalanced weights create a vibrating motion.

Spring System: The feeder tray is mounted on springs, which allow it to move freely in response to the vibrations generated by the motors.

Control System: This includes the electronic controls that regulate the frequency and amplitude of the vibrations, ensuring the feeder operates efficiently and consistently.

Loading: Coal is loaded into the hopper, which then releases it onto the feeder tray. The amount of coal released can be controlled by adjusting the opening of the hopper.

Vibration Generation: When the vibratory motors are activated, they create a rapid back-and-forth motion. The unbalanced weights on the motor shafts cause this motion, which is transferred to the feeder tray through the spring system.

Material Movement: The vibrations cause the coal on the feeder tray to move forward in small jumps. This movement is a combination of the vertical and horizontal components of the vibrations. The angle of the tray and the frequency of the vibrations determine the speed at which the coal moves.

Controlled Flow: The control system adjusts the vibration frequency and amplitude to ensure a steady and controlled flow of coal. This is crucial for downstream processes, such as crushing, screening, or feeding into a furnace.

Discharge: The coal moves along the feeder tray and is discharged at the end, where it can be collected or transferred to the next stage of the process.

Consistent Flow: Vibrating feeders provide a consistent and uniform flow of material, which is essential for efficient processing.

Adjustable: The flow rate can be easily adjusted by changing the vibration frequency and amplitude, allowing for precise control.

Durability: Vibrating feeders are built to withstand harsh conditions and abrasive materials like coal.

Low Maintenance: These feeders have relatively few moving parts, which reduces the need for frequent maintenance.

Energy Efficient: Vibrating feeders are generally energy-efficient, as they use the vibratory motion to move materials with minimal power consumption.

Vibrating feeders are used in various industries, including:

In summary, a vibrating feeder for coal works by using vibratory motors to generate a controlled vibrating motion, which moves the coal along a feeder tray. The system ensures a consistent and adjustable flow of material, making it an essential component in various industrial processes.