Reducing energy consumption in limestone crushing plants can have significant environmental and economic benefits. Here are several strategies to consider:

-

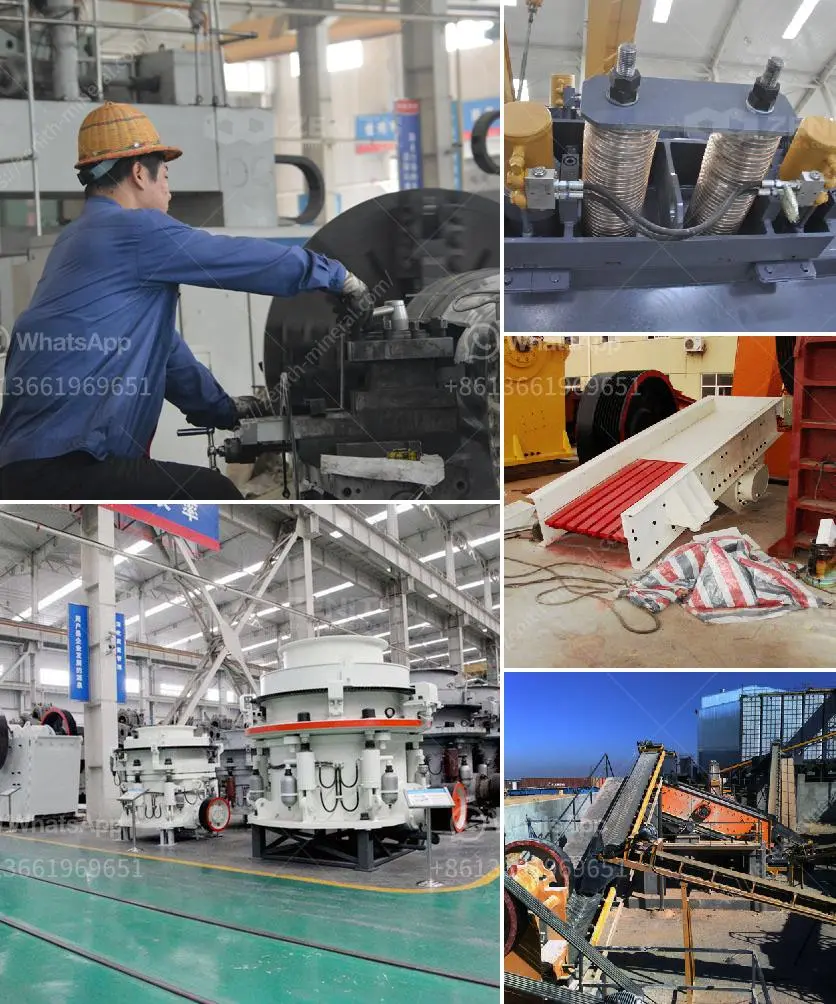

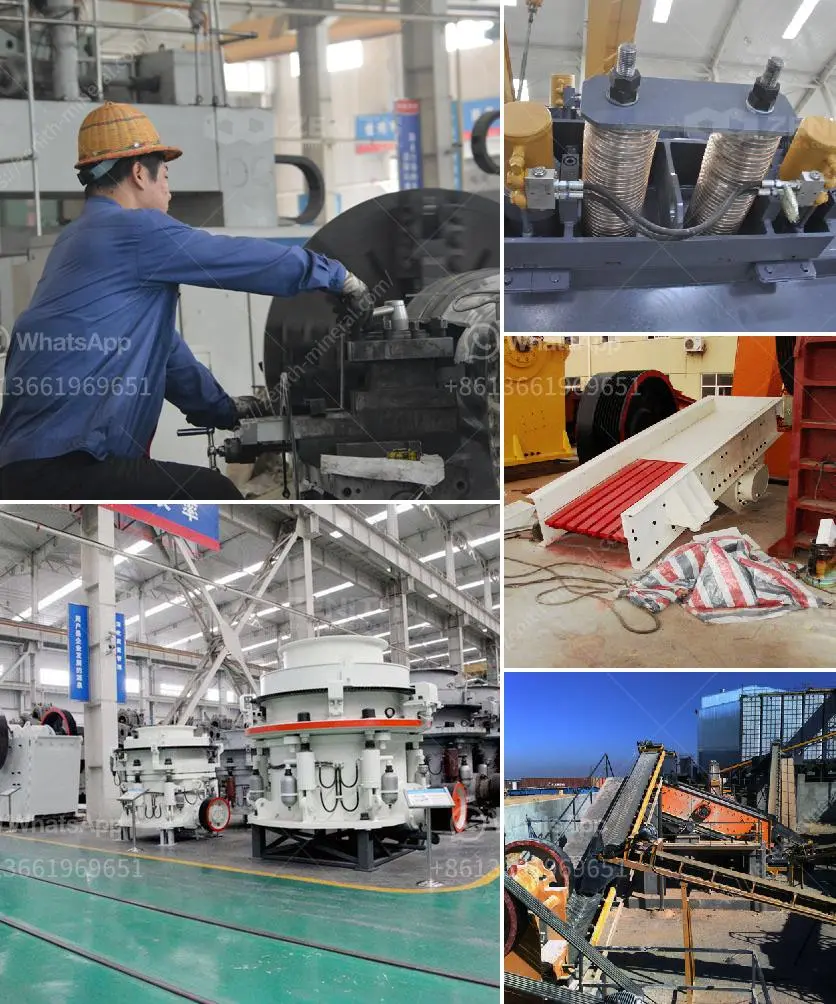

Efficient Equipment Selection:

- Choose energy-efficient crushers and grinding mills that match the required outputs.

- Implement the use of high-pressure grinding rolls (HPGR) which are more energy-efficient than conventional crushers.

-

Regular Maintenance:

- Perform regular maintenance on equipment to ensure they are operating efficiently.

- Replace worn-out parts to prevent extra energy use due to inefficiencies.

-

Process Optimization:

- Optimize crushing processes to operate at optimal load and speed.

- Use computer modeling and simulation to test different scenarios and find the most efficient configurations.

-

Automation and Control Systems:

- Employ advanced control systems that automate and optimize the crushing process.

- Utilize sensors and monitoring systems to adjust processes in real-time for energy savings.

-

Load Management:

- Avoid peak energy consumption periods by operating during off-peak hours if possible.

- Implement demand-side management techniques to better balance electricity usage.

-

Use of Renewable Energy Sources:

- Integrate renewable energy sources, such as solar or wind, to power plant operations.

- Explore cogeneration options to produce electricity as a byproduct of process heat.

-

Material Handling Improvements:

- Minimize unnecessary transfer and handling of materials to reduce energy use.

- Use conveyors and other systems that minimize material transport distance and time.

-

Pre-screening and Pre-sorting:

- Implement pre-screening techniques to remove fine material before entering the crusher.

- Use sorting technologies to improve the quality of the input material, thereby reducing the energy required for processing.

-

Employee Training and Awareness:

- Train employees on energy-saving practices and the importance of energy conservation.

- Encourage input from operators who can identify areas of potential waste.

-

Regular Energy Audits:

- Conduct regular energy audits to identify areas of excessive energy use.

- Implement suggested improvements from audits to enhance energy efficiency.

By applying these strategies, you can improve the energy efficiency of limestone crushing plants, ultimately reducing operational costs and environmental impact.