Quartz crushers and mining equipment are essential in extracting, crushing, and processing quartz from its natural state to a usable form for various industrial applications, such as glass making, electronics, and construction. Here are some key features of quartz crushers and mining equipment:

-

Material Hardness and Abrasion Resistance:

- Quartz is a very hard mineral (Mohs hardness 7), so equipment is designed to be robust, durable, and resistant to wear and tear.

-

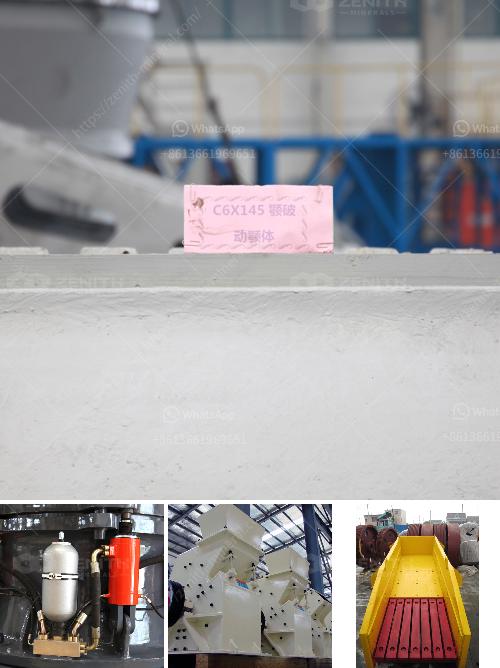

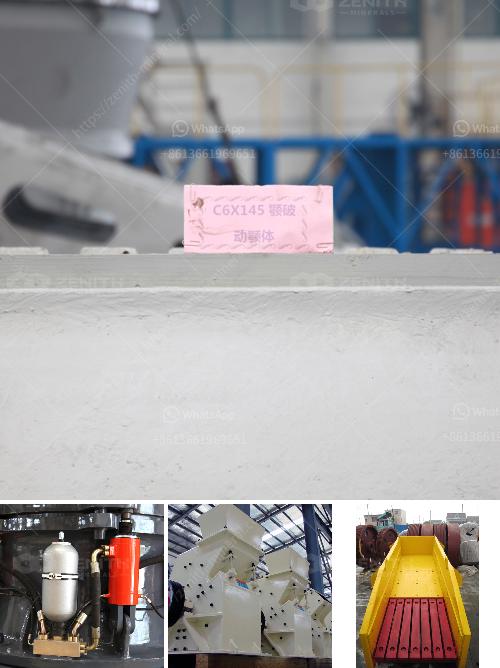

Crushing Technology:

- Crushers come in various types, including jaw crushers, impact crushers, cone crushers, and hammer mills, each suitable for different stages of crushing.

- Jaw crushers are used for primary crushing; they handle large, rough quartz pieces.

- Cone and impact crushers are often used for secondary crushing, providing more refined material sizes.

-

Efficiency and Capacity:

- High-capacity models designed to handle significant volumes of quartz for large operations.

- Energy-efficient features to reduce power consumption and operational costs.

-

Automation and Control Systems:

- Advanced systems with automated features to enhance control over crushing processes and improve precision in size and output gradation.

- Monitoring and diagnostic technology for preventive maintenance and reduced downtime.

-

Versatility and Scalability:

- Configurable setups that allow customization and adaptability to different mining scale operations, from small to large-scale productions.

- Modular designs that can integrate additional equipment, such as screens and conveyors.

-

Dust and Noise Control:

- Features like enclosed housing and dust suppression systems to minimize dust emission.

- Noise reduction technologies to comply with environmental standards and improve workplace safety.

-

Mobility and Portability:

- Mobile and portable crushing units for use in remote locations or quarry sites.

- Easy to transport and set up, which is important for operations that require relocation or temporary installations.

-

Maintenance and Accessibility:

- Design considerations for easy access to wear parts and maintenance areas, facilitating quick and efficient repairs.

- Spare parts availability and after-sales service to ensure uninterrupted operations.

-

Integration with Other Mining Equipment:

- Compatibility with other mining equipment, such as feeders, conveyors, and screening machines, to create a complete processing line.

- Ability to process other types of minerals if needed, enhancing overall utility.

-

Safety Features:

- Safety guards, emergency stop functions, and fail-safe mechanisms to protect operators and equipment.

These features collectively contribute to effective and efficient quartz crushing and processing in the mining industry, ensuring high-quality output while adhering to operational and environmental standards.