The process of removing impurities from kaolinite, a type of clay mineral, involves several steps to ensure the final product is of high quality and suitable for various industrial applications. Here is a detailed explanation of the methods used to purify kaolinite:

1. Mining and Initial Processing

- Mining: Kaolinite is typically extracted from open-pit mines. The raw material is often mixed with other minerals and impurities.

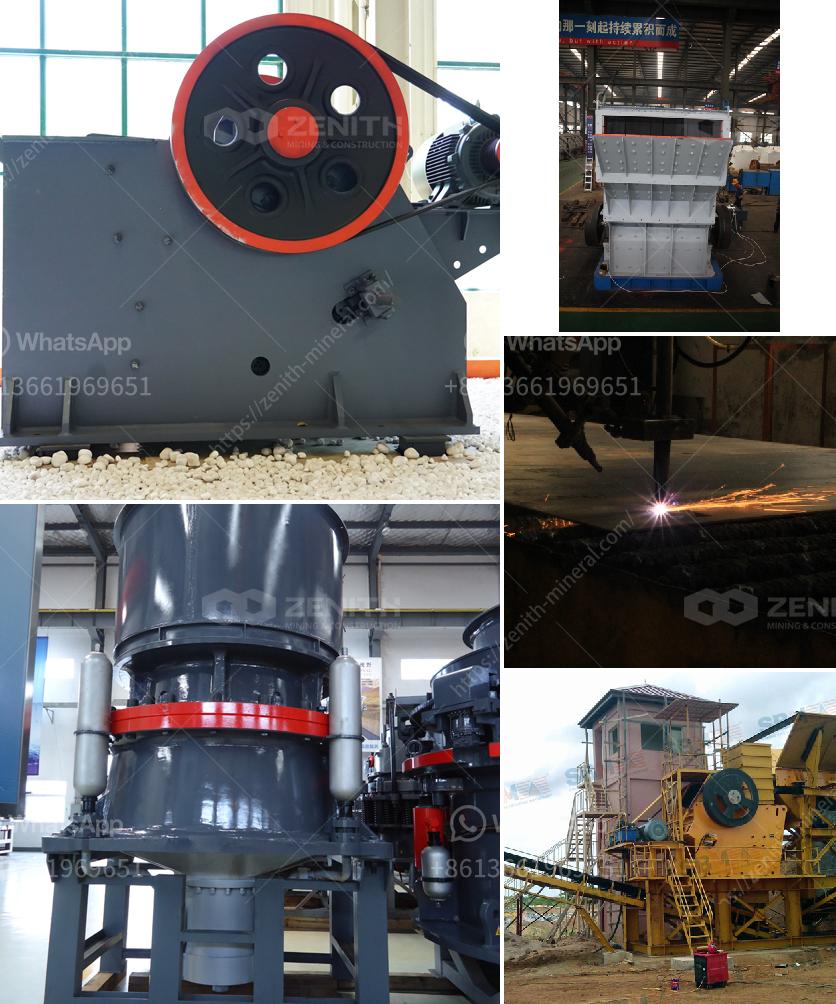

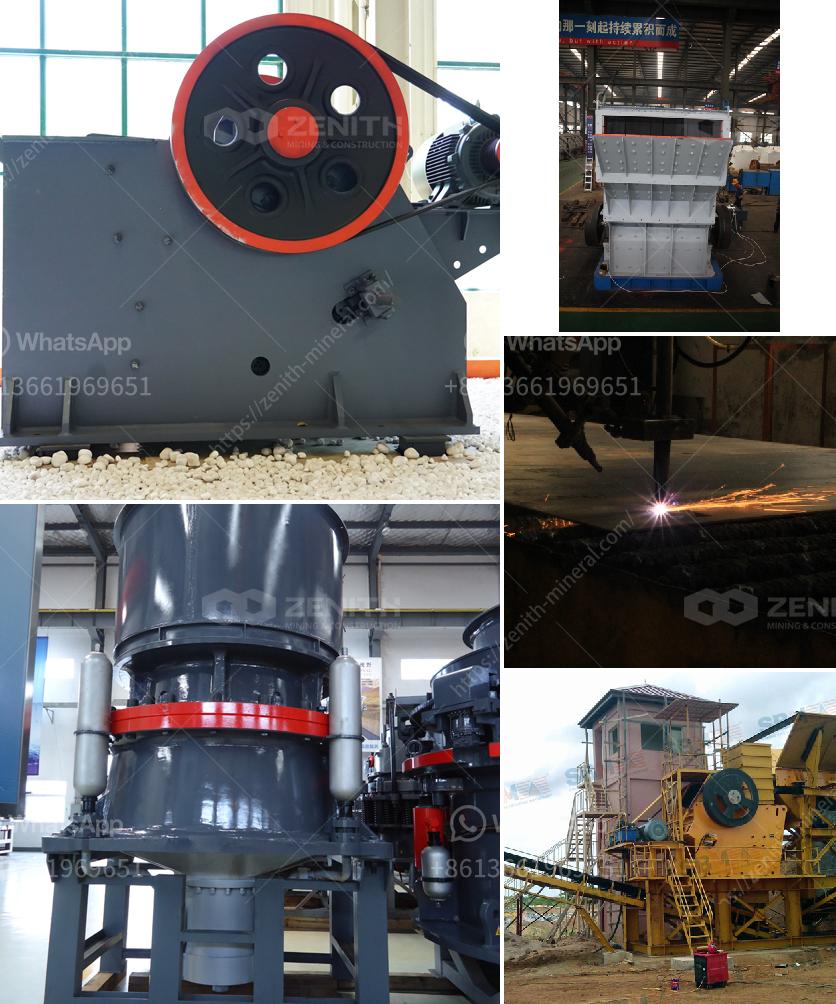

- Crushing and Grinding: The extracted kaolinite is crushed and ground to break down the large chunks into smaller particles, making it easier to handle and process.

2. Screening and Sieving

- Screening: The ground kaolinite is passed through screens to remove larger particles and debris. This step helps in separating the kaolinite from coarse impurities.

- Sieving: Further sieving can be done to classify the particles based on size, ensuring uniformity in the material.

3. Hydrocycloning

- Hydrocycloning: This process involves using a hydrocyclone, a device that separates particles in a liquid suspension based on their size and density. The kaolinite slurry is fed into the hydrocyclone, where centrifugal forces separate the finer kaolinite particles from coarser impurities.

4. Flotation

- Flotation: In this method, chemicals are added to the kaolinite slurry to create froth. The impurities attach to the bubbles and float to the surface, where they can be skimmed off. This process is particularly effective in removing iron and titanium impurities.

5. Magnetic Separation

- Magnetic Separation: This technique is used to remove magnetic impurities such as iron oxides. The kaolinite slurry is passed through magnetic separators, which attract and remove the magnetic particles.

6. Chemical Bleaching

- Chemical Bleaching: To further improve the whiteness and purity of kaolinite, chemical bleaching agents such as sodium dithionite or hydrogen peroxide are used. These chemicals help in reducing the color impurities and enhancing the brightness of the kaolinite.

7. Washing and Filtering

- Washing: The kaolinite is thoroughly washed with water to remove any remaining chemicals and impurities.

- Filtering: The washed kaolinite slurry is then filtered to remove excess water, resulting in a concentrated kaolinite paste.

8. Drying and Calcination

- Drying: The filtered kaolinite is dried to remove any remaining moisture. This can be done using rotary dryers or other drying equipment.

- Calcination: In some cases, the dried kaolinite is subjected to calcination, a process of heating the material to high temperatures in a kiln. Calcination helps in further improving the physical properties and purity of kaolinite.

9. Quality Control and Packaging

- Quality Control: The final product undergoes rigorous quality control tests to ensure it meets the required specifications for various applications.

- Packaging: The purified kaolinite is then packaged and stored for distribution.

Each of these steps plays a crucial role in ensuring that the kaolinite is free from impurities and suitable for use in industries such as ceramics, paper, paint, and cosmetics. The specific combination and sequence of these processes may vary depending on the nature of the raw kaolinite and the desired quality of the final product.