Installing a boltless liner on a tube mill is a specialized process that requires precision and attention to detail. Here's a general guide to help you with the installation:

Tools and Materials Needed:

- Boltless liners

- Rubber or composite materials for liners

- Adhesive or bonding agents (if required)

- Safety gear (gloves, goggles, etc.)

- Measuring tools

- Lifting equipment

- Cleaning tools (brushes, cloths, solvents)

Steps:

-

Safety First:

- Ensure that all safety protocols are followed. Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and hard hats.

-

Prepare the Mill:

- Shut down the mill and disconnect it from any power sources.

- Remove any existing liners, bolts, or other obstructions from the tube mill.

-

Clean the Interior:

- Thoroughly clean the interior surface of the mill. Any debris, dirt, or old adhesive must be removed to ensure proper bonding and fitment of the new liners.

-

Inspect the Shell:

- Inspect the tube mill shell for any damages or wear. Address any issues before proceeding with the installation.

-

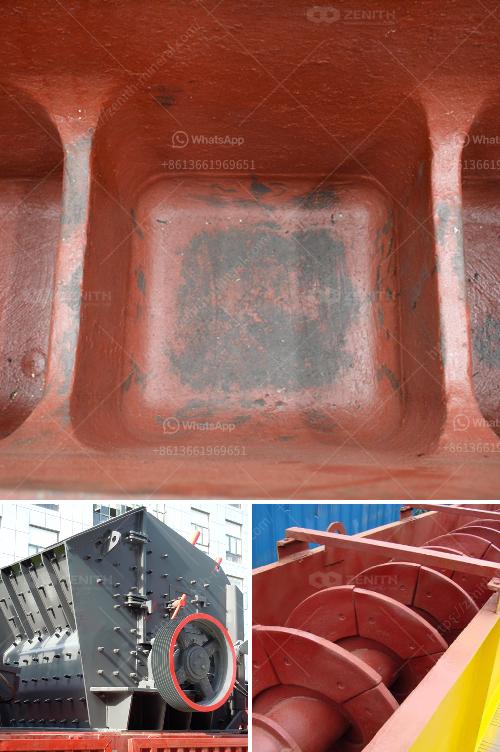

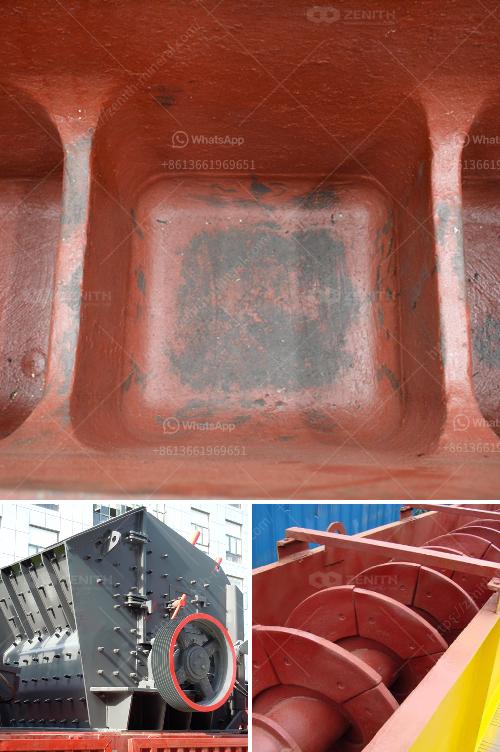

Measure and Cut the Liners:

- Measure the internal dimensions of the mill to ensure that the liners are cut to the correct size and shape. Precision is crucial for a secure fit.

-

Dry Fit the Liners:

- Place the liners inside the mill without any adhesive to check for proper fit. Make any necessary adjustments.

-

Apply Adhesive (if required):

- If the liners require adhesive, apply the recommended bonding agent evenly on the inside surface of the mill and on the back of the liners.

-

Install the Liners:

- Carefully install the liners inside the tube mill. Use lifting equipment to help position large or heavy sections. Ensure that each liner is properly aligned and seated against the mill shell.

-

Secure the Liners:

- Some boltless liners may have interlocking tabs or edges that need to be engaged. Ensure that all segments are securely interlocked or clamped as required.

-

Cure the Adhesive (if used):

- Allow the adhesive to cure according to the manufacturer’s instructions. This step is crucial to ensure that the liners remain securely in place during operation.

-

Inspect the Installation:

- After the adhesive has cured, inspect the entire installation to ensure that all liners are securely in place and properly aligned.

-

Reassemble and Test:

- Reconnect any components that were removed during the preparation process.

- Conduct a test run of the mill to ensure that the liners are functioning properly and are secure.

Final Checks

- Ensure that there is no excessive noise or vibration during the test run, as these could indicate misalignment or loose liners.

- Regularly inspect the liners after installation to monitor for wear and ensure longevity.

By following these steps, you should be able to successfully install boltless liners on your tube mill, enhancing its performance and extending its operational life. If you're unsure or it's your first time, it might be helpful to consult with or hire a professional who specializes in tube mill maintenance and liner installation.