Processing silica sand involves several steps to ensure its suitability for specific industries, such as glass-making or sandblasting. Here’s a general outline of the process:

-

Mining: Silica sand is mined from open pit or dredging operations. The raw sand must be high-quality and free from contaminants.

-

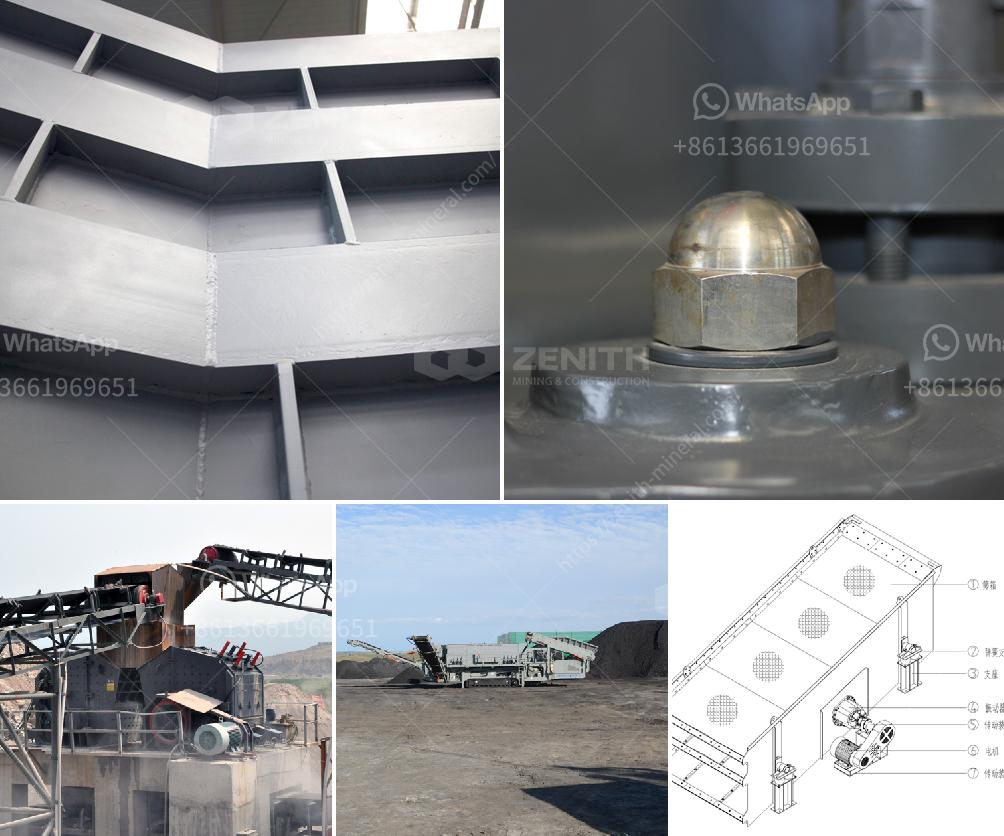

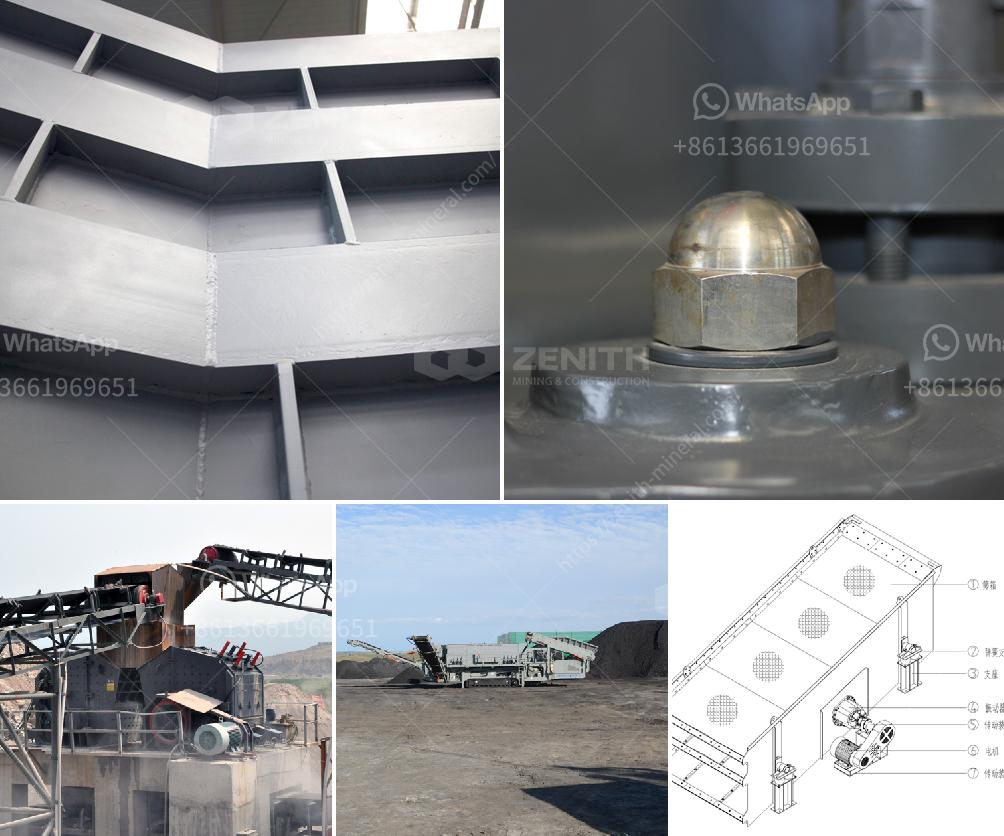

Crushing & Screening:

- Crushing: The mined silica sand is transported to the processing plant where it is crushed to break down the large chunks into smaller particles.

- Screening: The crushed sand is then screened to separate the larger particles from finer sand and to remove any impurities.

-

Washing:

- Washing: The screened sand is washed to remove the clay, silt, and other impurities. This is typically done using water and various washing techniques.

- Attrition Scrubbing: For some plants, sand grains are scrubbed in a high-energy attrition machine to remove the iron coating on the particles.

-

Gravity Separation:

- The washed sand is further subjected to gravity separation methods, such as shaking tables, spiral separators, or hydrocyclones, to enhance the purity by removing heavy mineral sands and other impurities.

-

Magnetic Separation:

- This step involves separating the iron-bearing contaminants using magnetic separators. For silica sand used in the glass industry, this is particularly important, as iron impurities can affect the clarity and color of the glass.

-

Drying:

- After washing and separating, the wet sand is dried in rotary or fluid bed dryers to reduce the moisture content, making it suitable for various industrial applications.

-

Sizing:

- The dried sand is classified according to particle size using vibrating screens or air classifiers. This ensures uniformity and meets the specifications for specific applications.

-

Quality Control:

- The processed sand is sampled and tested for quality control. Parameters such as grain size distribution, silica content, and the presence of impurities are analyzed to ensure that the sand meets the required standards.

Once these steps are complete, the processed silica sand is packaged and transported to customers for a variety of uses, including glass manufacturing, foundry casting, filtration, and more.