The process that crushes basalt, a common extrusive igneous rock, involves several stages and can be carried out using various types of machinery and techniques. Here is a detailed explanation of the process:

Extraction: Basalt is typically extracted from quarries or mines. This involves drilling, blasting, and removing large chunks of basalt from the earth. The extracted basalt is then transported to a processing facility.

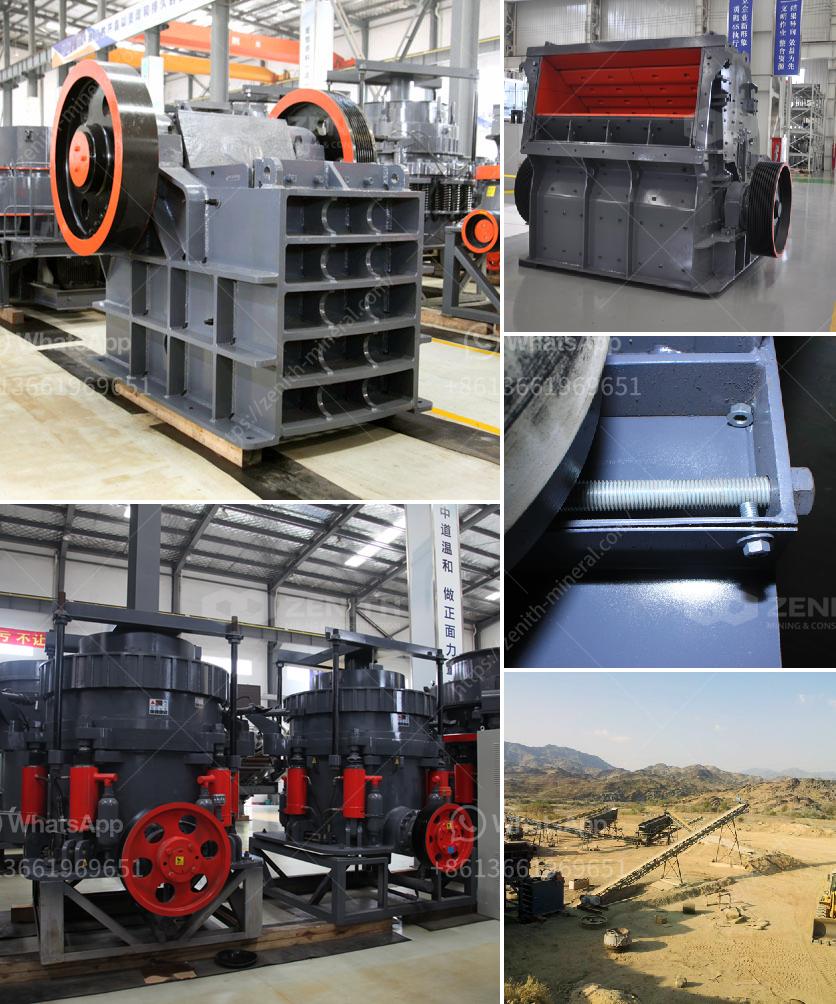

Primary Crushing: At the processing facility, the large chunks of basalt are fed into a primary crusher. This is usually a jaw crusher or a gyratory crusher. The primary crusher reduces the size of the basalt chunks to a manageable size, typically around 6 to 10 inches in diameter.

Secondary Crushing: The material from the primary crusher is then fed into a secondary crusher. This can be a cone crusher, impact crusher, or hammer mill. The secondary crusher further reduces the size of the basalt to smaller, more uniform pieces, typically less than 2 inches in diameter.

Screening: After secondary crushing, the material is screened to separate it into different size fractions. This is done using vibrating screens or rotary screens. The screening process ensures that the crushed basalt meets the required specifications for its intended use.

Tertiary Crushing (if needed): In some cases, a tertiary crushing stage is required to achieve the desired size and shape of the basalt particles. This can involve additional cone crushers, impact crushers, or vertical shaft impactors (VSIs).

Washing and Cleaning: Depending on the end use of the crushed basalt, it may need to be washed and cleaned to remove any dust, dirt, or impurities. This is typically done using water and mechanical scrubbing.

Stockpiling and Distribution: The final step in the process is to stockpile the crushed basalt and prepare it for distribution. The material is typically stored in large piles or silos and then loaded onto trucks or trains for transport to its final destination.

The entire process of crushing basalt is designed to produce a material that is suitable for use in construction, road building, and other applications where a strong, durable aggregate is required. The specific machinery and techniques used can vary depending on the size and hardness of the basalt, as well as the desired final product.