In iron ore crushing processes, several types of equipment are commonly used to ensure efficient and effective reduction of the ore to the desired size. These typically include:

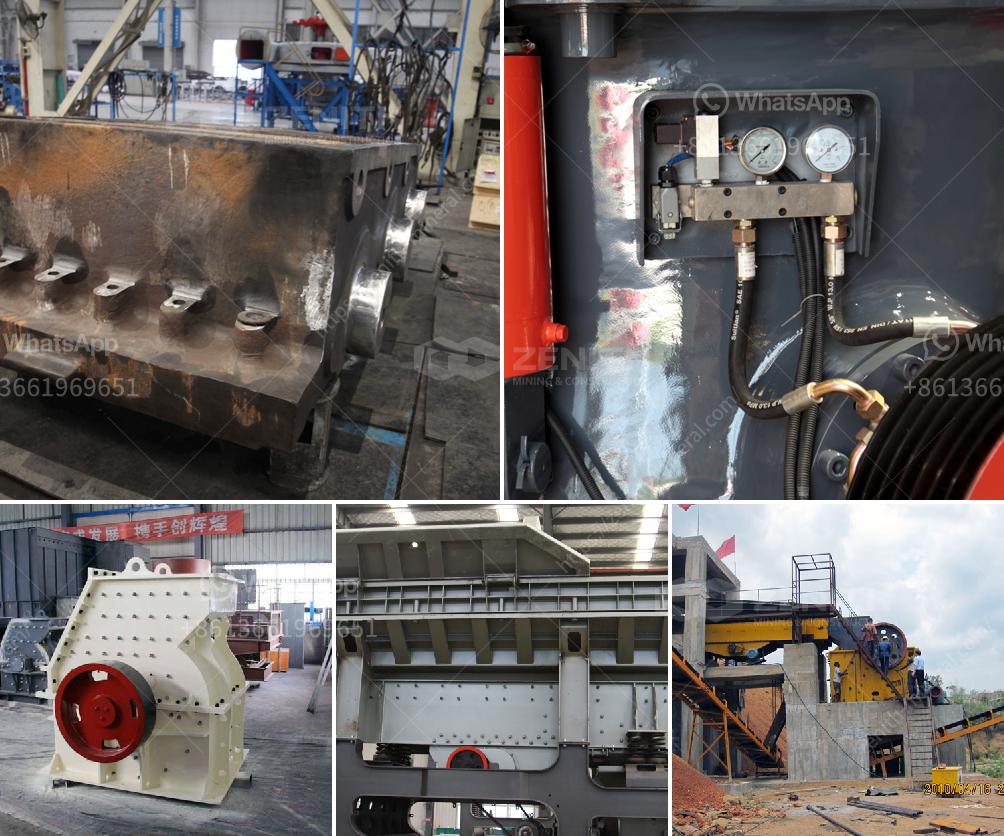

Jaw Crushers: These are used for primary crushing, where large pieces of iron ore are broken down into smaller, manageable sizes.

Gyratory Crushers: Similar to jaw crushers, gyratory crushers are used for primary crushing but can handle larger quantities of ore.

Cone Crushers: These are used for secondary and tertiary crushing stages. Cone crushers offer excellent fine crushing capabilities.

Impact Crushers: Suitable for medium to fine crushing, impact crushers use impact force to break down the ore.

Hammer Mills: These devices use rotating hammers to crush ore into finer particles, useful for achieving more uniform material.

Vibrating Screens: After crushing, these screens are used to sort and separate the crushed ore into different size fractions.

Roll Crushers: Utilized for secondary or fine crushing, roll crushers apply high pressure to the ore, making them suitable for producing smaller-sized particles.

Grinding Mills: Although not always included in the initial crushing phase, they are important for further size reduction and preparation for subsequent processing.

Feeders: Various types of feeders (e.g., apron feeders, grizzly feeders) are used to regulate the flow of ore between crushing stages and to ensure consistent feed to crushers.

Selecting the right combination of these pieces of equipment depends on the specific characteristics of the iron ore being processed, including its hardness, abrasiveness, and desired final product size.