Choosing a vibrating feeder involves several key considerations to ensure it meets your specific needs and application requirements. Here’s a step-by-step guide to help you make an informed decision:

-

Material Characteristics:

- Type of material: Consider the type of material (granular, powder, aggregate) you will be moving.

- Material properties: Look at factors such as bulk density, moisture content, particle size, and abrasiveness.

-

Capacity and Throughput:

- Determine the amount of material that needs to be moved per unit time.

- Match the feeder size and capacity with your required throughput rates.

-

Mounting Options:

- Decide whether you need a suspension or base-mounted feeder.

- Consider the space available for installation and how the feeder will integrate with your existing equipment.

-

Feeding Mechanism:

- Choose between an electromagnetic or electromechanical feeder depending on your application's needs.

- Electromagnetic feeders are more controllable, suitable for precise feeding, while electromechanical feeders are typically more robust, handling heavier loads.

-

Power Requirements:

- Check the power requirements and ensure it matches your facility's power supply.

- Consider energy efficiency for cost-effective operation.

-

Control Features:

- Look for feeders with adjustable feed rates and control options to suit your operational needs.

- Advanced models may offer digital controls for precise feed regulation.

-

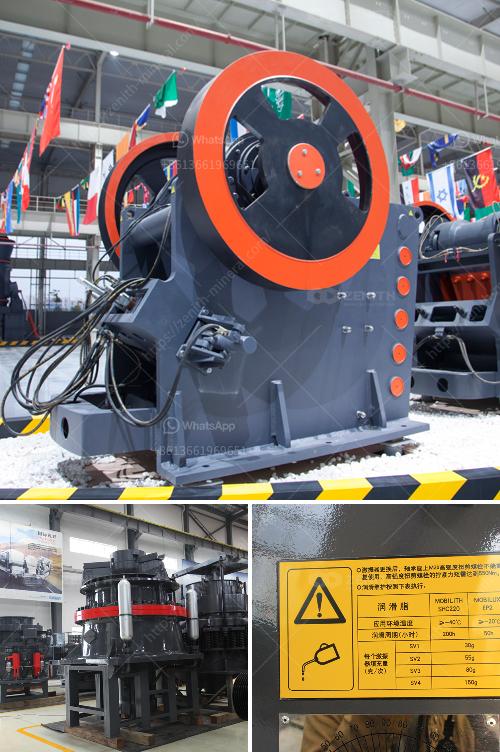

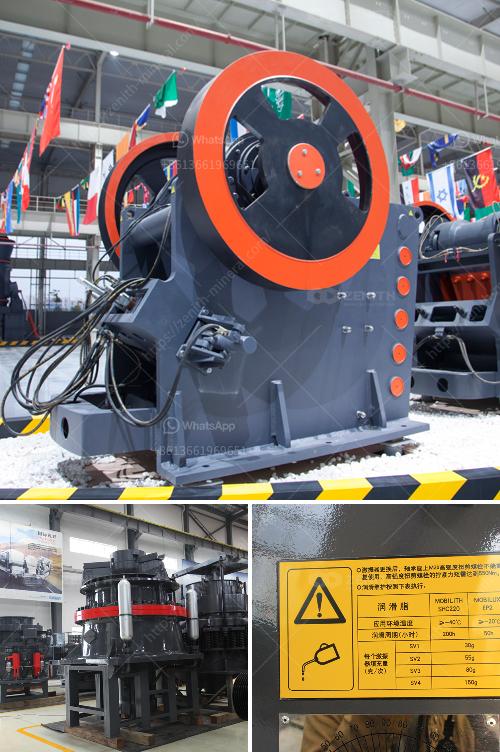

Construction and Durability:

- Ensure the construction materials of the feeder can withstand the operating environment.

- Stainless steel is commonly chosen for its durability and resistance to corrosion.

-

Ease of Maintenance:

- Choose a feeder that is easy to maintain and has readily available spare parts.

- Consider the design in terms of cleaning and wear part replacement access.

-

Noise and Vibration Levels:

- Assess the noise and vibration levels the feeder produces, ensuring they are compatible with your facility’s requirements for a safe and comfortable working environment.

-

Cost:

- Balance the initial investment with long-term operational costs.

- Consider not only the purchase price but also the potential benefits in productivity and reduced maintenance costs.

-

Manufacturer Support and Reputation:

- Opt for a reputable manufacturer who offers good customer support, warranties, and after-sales service.

- Check reviews, case studies, or references from other users in your industry.

By carefully considering these factors, you can select a vibrating feeder that optimally fits your operational needs and ensures efficient, reliable material handling.