Improving the lifespan of a coal crusher hammer involves several strategies aimed at reducing wear and tear. Here are some effective methods:

-

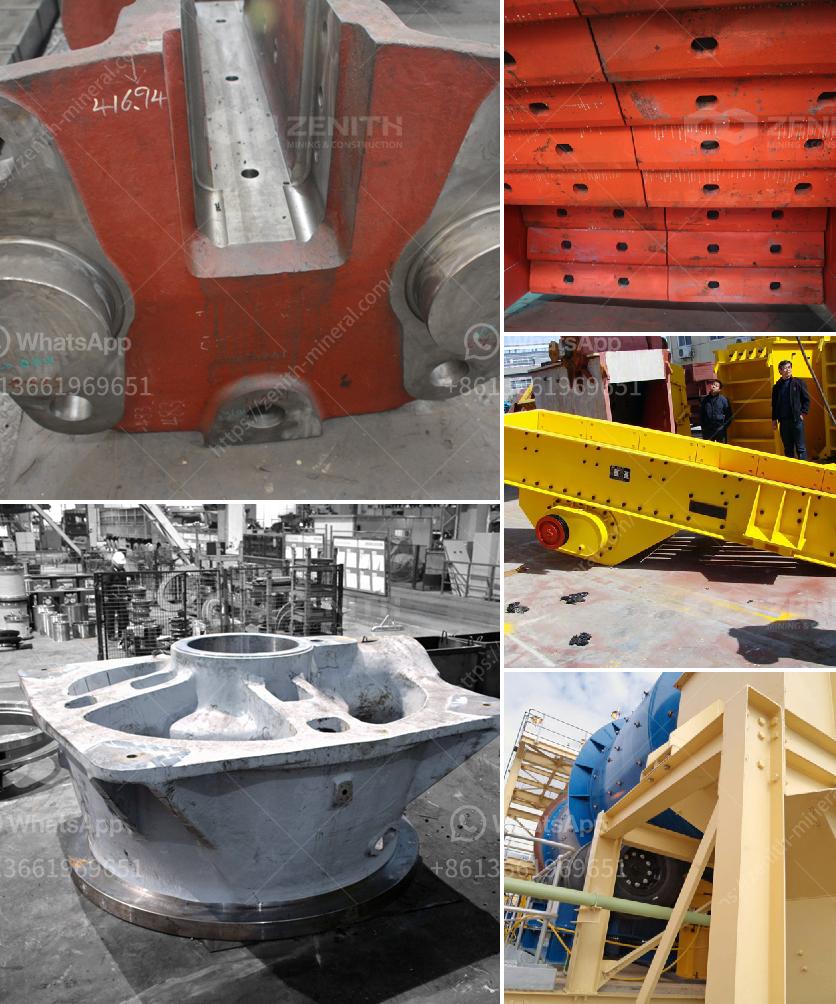

Material Selection:

- High-quality Material: Use high-manganese steel or other wear-resistant alloys for hammers. These materials can withstand the heavy impact and abrasion from coal.

- Composite Materials: Consider using composite materials that blend metals for enhanced durability.

-

Heat Treatment:

- Proper Hardening: Implement heat treatment processes to achieve the desired hardness and toughness of the hammer.

- Surface Hardening: Techniques like carburizing or induction hardening can improve the surface strength.

-

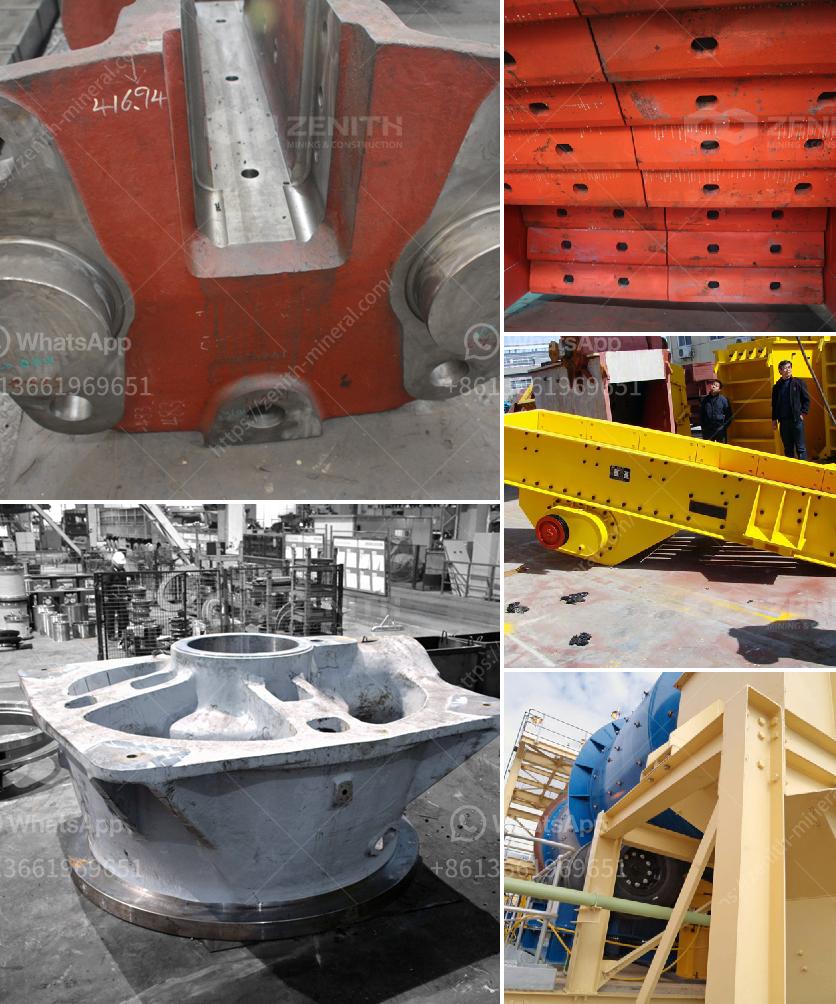

Design Modifications:

- Optimized Shape: Design the hammers with shapes that reduce stress concentrations. Rounded edges can reduce the likelihood of cracks.

- Symmetry: Ensure the hammers are balanced and symmetrical to avoid uneven wear.

-

Maintenance and Inspection:

- Regular Inspections: Conduct frequent checks for signs of wear or damage. Replace hammers before they fail completely.

- Consistent Lube: Proper lubrication can reduce friction and wear.

-

Operational Adjustments:

- Feed Size Control: Ensure that the coal feed size is within the crusher's optimal range. Oversized material can cause excessive wear.

- Reduce Overloading: Do not overload the crusher. Overloading can lead to increased wear and premature failure.

-

Protective Linings and Coatings:

- Hardfacing: Apply hardfacing materials to the hammer surface to enhance wear resistance.

- Protective Coatings: Use specialized coatings to protect the hammer from abrasion and corrosion.

-

Improved Crushing Methods:

- Pre-Screening: Remove fine materials before they enter the crusher. Fines can accelerate wear on hammers.

- Controlled Feed Rate: Implement a controlled feed rate to ensure the crusher is operating efficiently.

By integrating these measures, you can significantly extend the lifespan of your coal crusher hammers, improving the overall efficiency and reducing operational costs.