Setting up an artificial sand plant involves various steps, each requiring careful planning and execution. Here’s a detailed guide to help you through the process:

Step 1: Research and Feasibility Study

- Market Demand Analysis: Assess the demand for artificial sand in your target market.

- Resource Availability: Ensure the availability of raw materials like crushed stone, gravel, etc.

- Location Selection: Choose a site with adequate space, accessibility to raw materials, and proximity to the market.

Step 2: Plant Design and Layout

- Site Preparation: Clear and level the land. Ensure proper drainage to avoid waterlogging.

- Plant Layout: Design the layout to optimize the workflow, storage, and transportation of materials.

- Environmental Considerations: Plan for dust suppression, waste management, and compliance with local environmental regulations.

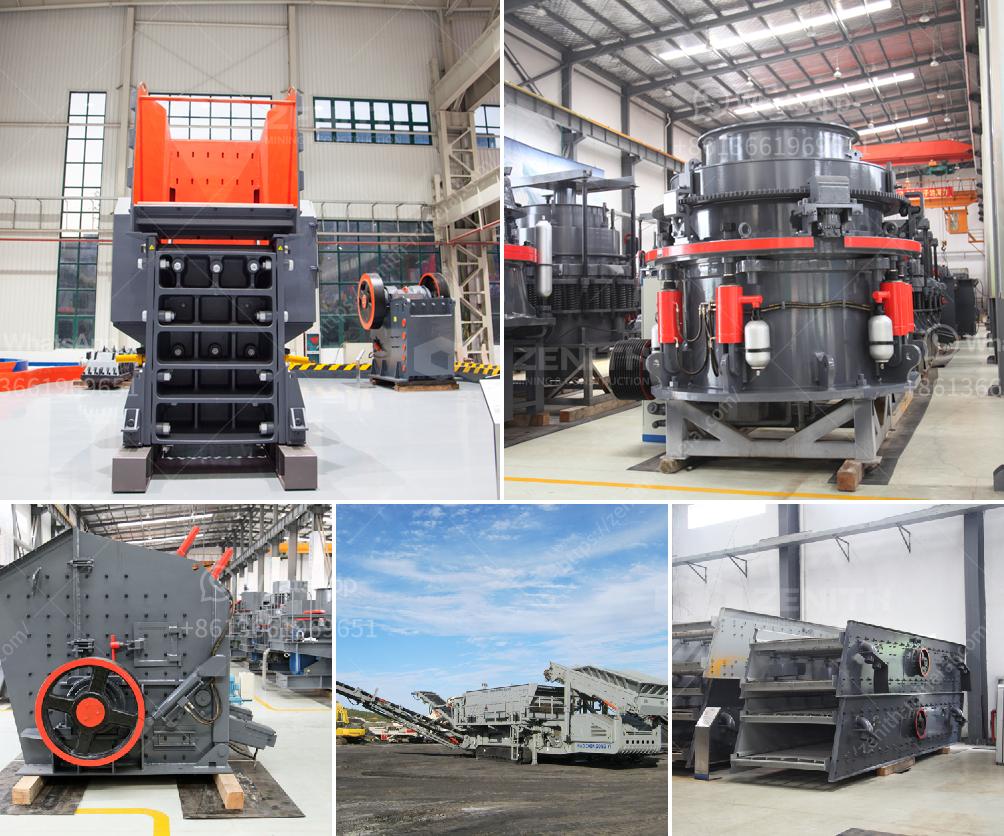

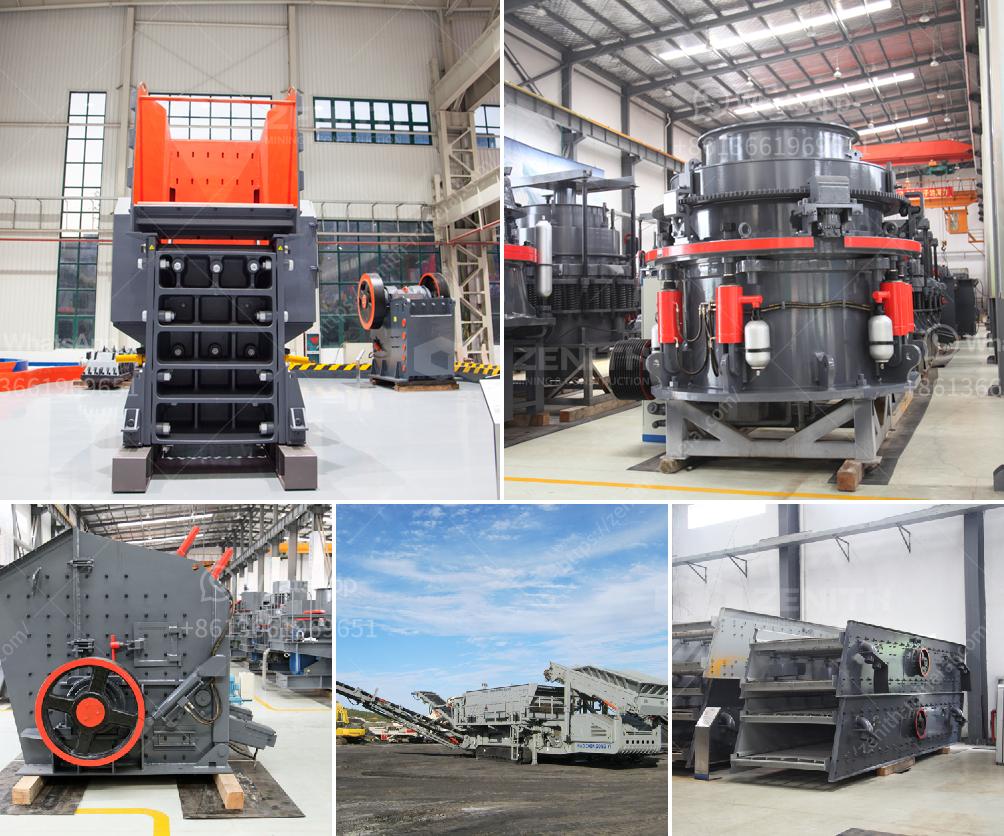

Step 3: Equipment Selection

- Primary Crushers: Choose jaw crushers for initial size reduction of raw materials.

- Secondary Crushers: Select impact crushers or cone crushers for further reduction.

- Sand Making Machines: Use sand making machines like VSI (Vertical Shaft Impact) crushers.

- Screening Equipment: Install vibrating screens to separate different sizes of sand.

Step 4: Infrastructure Development

- Power Supply: Ensure a reliable electricity source with adequate capacity.

- Water Supply: Necessary for dust suppression and equipment cooling.

- Transportation Access: Build roads for easy transportation of raw materials and finished products.

Step 5: Legal and Regulatory Compliance

- Permits and Licenses: Obtain necessary permits for mining, environmental clearance, and plant operation.

- Quality Standards: Comply with local quality standards for artificial sand production.

Step 6: Installation and Commissioning

- Equipment Installation: Set up crushers, conveyors, screens, and sand-making machines as per the manufacturer's instructions.

- Testing: Test the equipment to ensure proper functioning and production output.

- Training: Train the workforce on operating equipment safely and efficiently.

Step 7: Production and Quality Control

- Raw Material Feeding: Feed raw materials into the primary crusher.

- Crushing and Screening: Process the raw materials through the crushers and screens.

- Sand Making: Pass the crushed material through sand-making machines to produce artificial sand.

- Quality Control: Regularly test the quality of the produced sand to ensure it meets required standards.

Step 8: Marketing and Sales

- Branding: Develop a brand for your artificial sand.

- Sales Channels: Establish connections with construction companies, retailers, and distributors.

- Pricing Strategy: Set competitive prices based on market demand and production costs.

Step 9: Continuous Improvement

- Customer Feedback: Collect feedback to improve product quality and service.

- Technology Upgrades: Invest in advanced machinery and techniques to enhance efficiency and reduce costs.

- Employee Training: Continuously train employees on best practices and safety measures.

By following these steps, you can successfully set up an artificial sand plant that meets market demands and operates efficiently.