Setting up a stone crusher unit involves several key steps. Here's a general guide to help you get started:

-

Conduct a Feasibility Study:

- Analyze the market demand for crushed stone in your region.

- Identify the potential customers and competitors.

- Evaluate the financial viability, including the cost of equipment, labor, utilities, and other expenses.

-

Choose a Suitable Location:

- Ensure the site is easily accessible for transporting raw materials and finished products.

- Check for proximity to raw material sources like quarries.

- Confirm the site complies with local zoning regulations and environmental laws.

-

Obtain Necessary Permits and Licenses:

- Apply for environmental clearance from the local authorities.

- Obtain land use and building permits.

- Secure necessary licenses for operating a stone crusher unit.

-

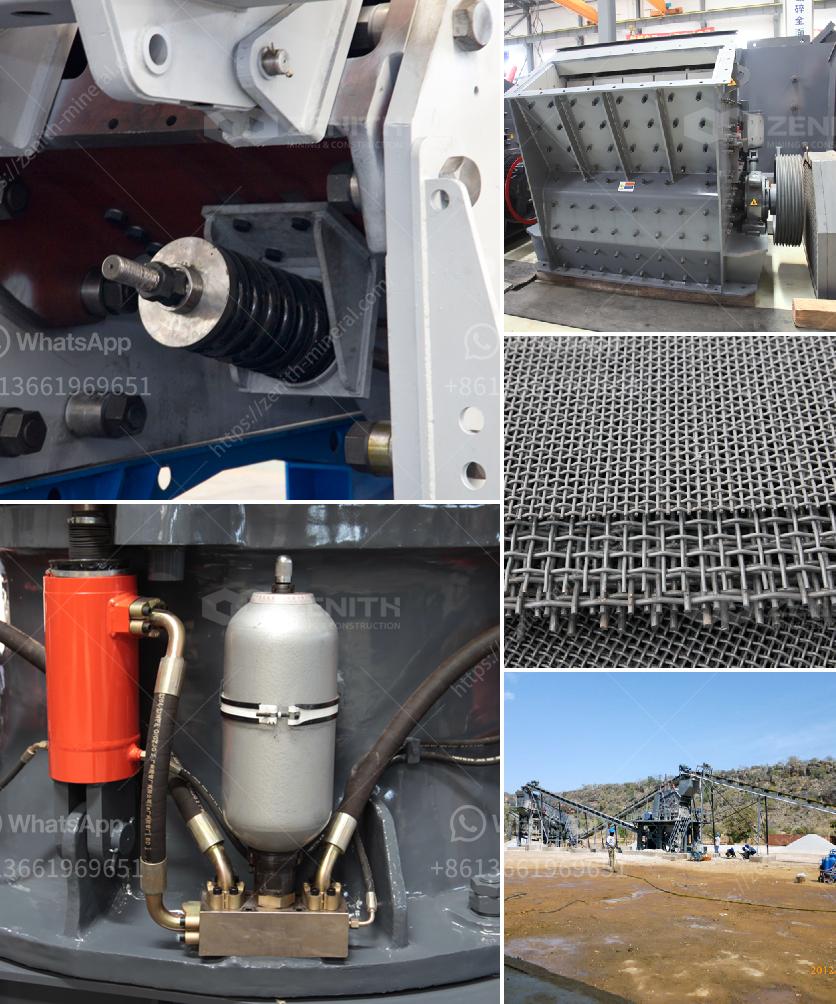

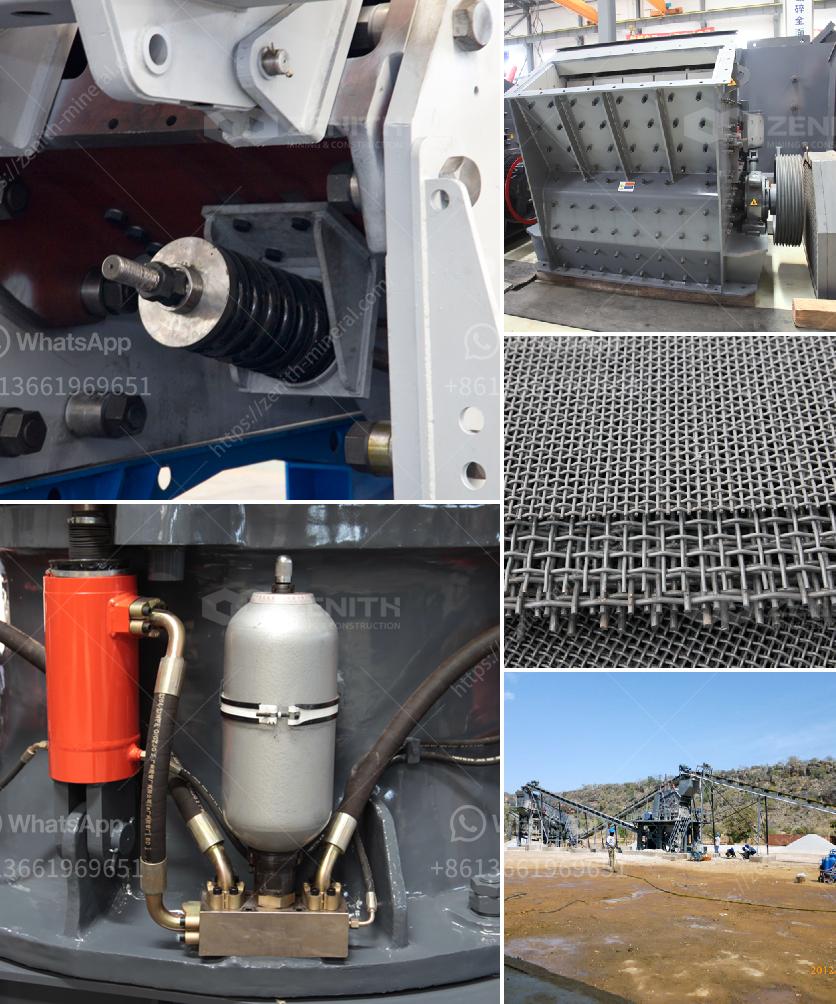

Procure Equipment and Machinery:

- Choose appropriate crushers (jaw crusher, impact crusher, cone crusher, etc.) based on the type of stones and the required product size.

- Purchase conveyors, screens, and other auxiliary equipment.

- Consider transportation vehicles for moving finished products.

-

Install and Set Up Equipment:

- Prepare the site by leveling the ground and constructing necessary buildings or shelters for machinery.

- Install the crushing equipment and other machinery according to manufacturer guidelines.

- Connect power, water supply, and other utilities.

-

Hire and Train Staff:

- Recruit skilled operators and laborers familiar with crushing operations.

- Provide training on safe operating practices and machinery maintenance.

-

Set Up Operational Procedures:

- Develop standard operating procedures (SOPs) for crusher operation, maintenance, and safety.

- Establish quality control measures to ensure consistent product quality.

-

Implement Safety Protocols:

- Equip staff with personal protection equipment (PPE).

- Install safety guards and emergency stop mechanisms on machinery.

- Conduct regular safety drills and inspections.

-

Launch Operations:

- Start with a trial run to ensure everything is functioning correctly.

- Monitor the production process closely and make necessary adjustments.

- Begin full-scale operations and gradually scale up production.

-

Market and Distribute Products:

- Develop a marketing strategy to reach potential customers.

- Set up a logistics plan for delivering products efficiently.

- Build relationships with contractors, builders, and other end-users.

These steps provide a foundational approach but be sure to tailor them to your specific context and regulatory environment.