Budgeting for equipment wear in abrasive granite operations requires a careful assessment of several factors to ensure cost-effectiveness and operational efficiency. Here is a detailed approach:

-

Understand Equipment Usage and Lifespan:

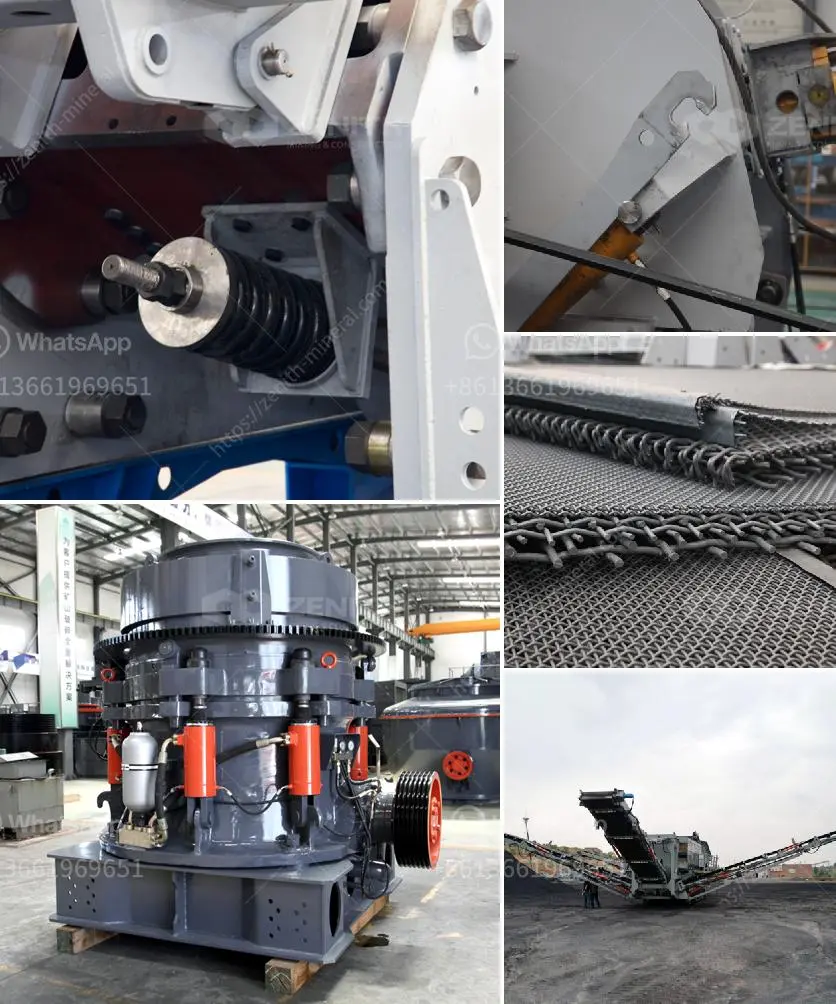

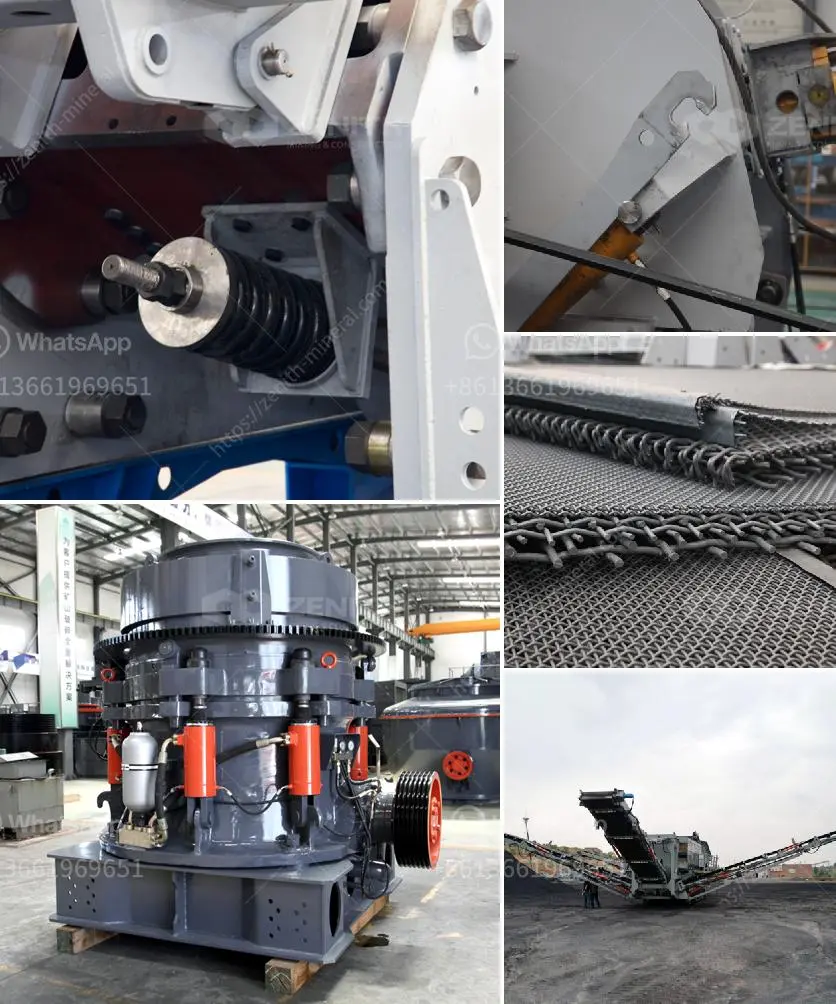

- Identify the types of equipment used in granite operations, such as saws, crushers, loaders, and conveyors.

- Determine the average lifespan of each type of equipment under typical operating conditions.

-

Assess Wear Factors:

- Recognize the abrasive nature of granite and how it contributes to accelerated wear and tear on equipment.

- Study factors such as operation hours, maintenance routine, and specific operating conditions that can impact wear rates.

-

Maintenance and Inspection Schedules:

- Develop a regular maintenance schedule to monitor wear and address issues before they lead to failures.

- Use this data to estimate the frequency and cost of repairs or replacements.

-

Historical Data Analysis:

- Analyze past records of equipment maintenance, repair, and replacement costs.

- Use historical data to identify trends and estimate future wear-related expenses.

-

Budget for Consumables and Spare Parts:

- Include costs for consumables such as cutting tools, bearings, and lubrication.

- Maintain a stock of critical spare parts, factoring these into the budget to minimize downtime.

-

Predictive Maintenance Technologies:

- Invest in technologies like sensors and IoT devices for real-time monitoring of equipment condition.

- Predictive maintenance can help in foreseeing potential issues and reducing unexpected repair costs.

-

Operator Training and Best Practices:

- Train operators on best practices for equipment use to minimize improper handling and excess wear.

- Implement operational procedures that reduce the abrasive impact on equipment.

-

Insurance and Contingency Planning:

- Consider purchasing equipment insurance to cover unexpected major failures.

- Allocate funds for unforeseen breakdowns or major repairs in the contingency budget.

-

Regular Review and Adjustment:

- Periodically review the budget against actual expenses and adjust estimates based on operational changes or new data.

- Continuously update maintenance strategies and budgeting techniques as new technologies and methodologies emerge.

By systematically evaluating these areas, you can create a comprehensive budget that accounts for expected wear and tear in abrasive granite operations while maintaining financial control over maintenance expenses.