Using a stationary quarry rock crusher for primary crushing comes with several benefits, including:

High Capacity and Efficiency: Stationary rock crushers are designed for large-scale operations. They can handle large quantities of rock and produce consistent product sizes efficiently, making them ideal for high-volume applications.

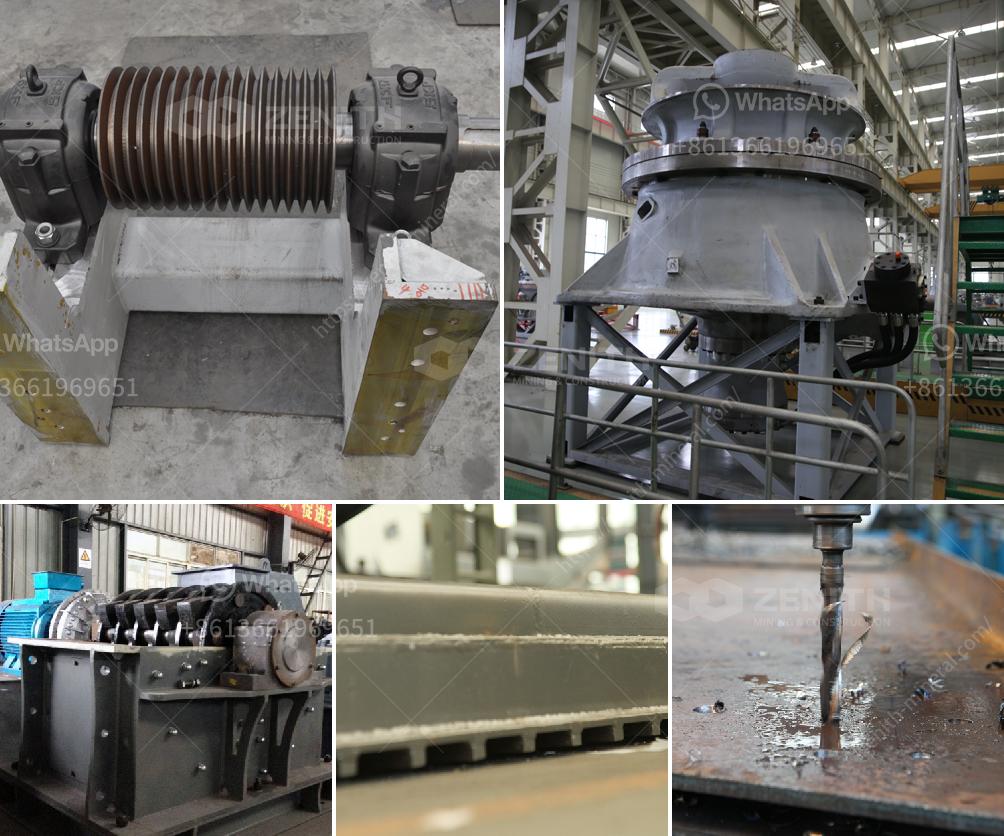

Durability and Longevity: Since stationary crushers are fixed in one location, they can be built with more robust materials and structures, leading to increased durability and a longer operational lifespan when compared to mobile crushers.

Cost-Effective: Over time, stationary crushing solutions can be more cost-effective than mobile units due to their larger capacity, lower operating costs, and reduced need for frequent relocation. They also have lower wear and maintenance costs.

Consistent Production Quality: Stationary crushers provide better control over particle size and product consistency. This is vital for operations that require precise aggregate sizes or have strict quality standards.

Energy Efficiency: These crushers often consume less energy for the same level of output, partly because they are optimized for fixed-site operations and do not have to be as versatile as mobile units.

Integration with Other Equipment: Stationary rock crushers can be easily integrated with other quarry equipment like conveyors, screens, and washing plants, facilitating seamless operation and process automation.

Reduced Environmental Impact: By being permanently installed, stationary crushers minimize the disturbance to the work site compared to mobile crushers, which require movement and can cause more noise and dust pollution.

Improved Safety: Since the equipment is fixed and does not move, there may be fewer safety risks associated with equipment relocation or instability. This setup allows for safer operational protocols.

Ease of Maintenance: With stationary crushers, maintenance is often easier and more convenient because technicians can access the equipment more readily and use advanced tools and lifting machinery that are often available at larger, permanent setups.

Customization: Stationary crushers can be custom-designed and tailored to the specific needs of a quarry, taking into account the type and hardness of rock, the size of the quarry, and other unique operational requirements.

Overall, the choice of using a stationary quarry rock crusher for primary crushing largely depends on the scale of operations, budget, and specific project requirements. It is essential to weigh these benefits against the flexibility and upfront costs when making a decision.