Determining the total length of a belt conveyor involves several steps and can vary depending on the type of conveyor system and its layout. Here are the general steps to calculate it:

-

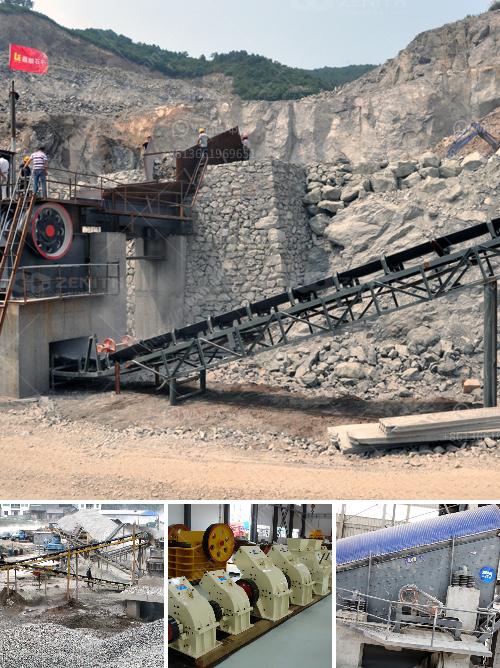

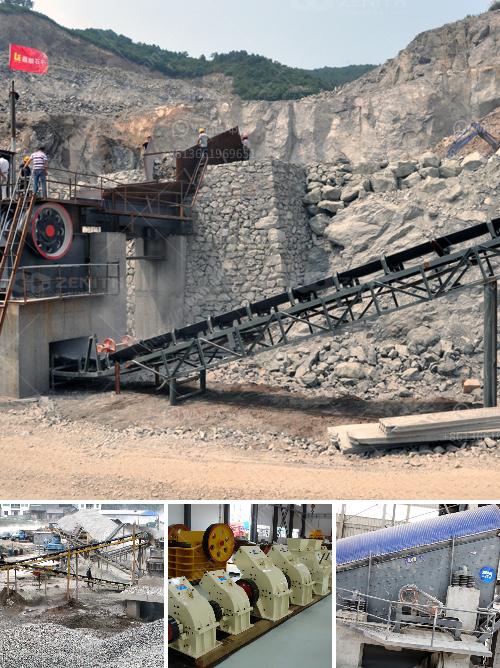

Identify the Conveyor Layout: Determine the configuration of your conveyor. Common layouts include straight lines, loops, and inclines. Note any curves, slopes, or changes in direction.

-

Measure Straight Sections:

- Use a measuring tape to determine the length of each straight section.

- Sum the lengths of all straight sections.

-

Account for Curves and Turns:

- If the conveyor has curves, measure the arc length of each curve. This can be done using the formula for the circumference of a circle section: ( L_{arc} = \theta \times r ), where ( \theta ) is the angle in radians and ( r ) is the radius of the curve.

- Sum the lengths of all the curves.

-

Calculate Changes in Elevation:

- If the conveyor has inclined or declined sections, measure the straight-line distance of these segments.

- Use the Pythagorean theorem to find the actual conveyor length in inclined sections: ( L_{incline} = \sqrt{(horizontal \, length)^2 + (vertical \, height)^2} ).

-

Sum All Sections:

- Add the lengths of all straight sections, curved sections, and inclined/declined sections together to get the total length of the conveyor.

Example:

Let's assume a conveyor with the following sections:

- Two straight sections of 10 meters each.

- One curve with a 90-degree angle and a radius of 2 meters.

- One incline section with a horizontal length of 5 meters and a vertical height of 3 meters.

- Straight sections:

- Curved section:

- ( L_{arc} = \theta \times r = \frac{90}{360} \times 2 \times \pi \times 2 = \frac{1}{4} \times 2 \times \pi \times 2 = \pi = 3.14 ) meters.

- Incline section:

- ( L_{incline} = \sqrt{(5)^2 + (3)^2} = \sqrt{25 + 9} = \sqrt{34} = 5.83 ) meters.

Total Length:

- ( 20 + 3.14 + 5.83 = 28.97 ) meters.

Always double-check measurements and calculations, and consider any additional factors particular to your conveyor system.