Building a rock crusher in Nigeria involves several steps, and it's important to prioritize safety and proper planning. Here's a general guide to help you get started:

Materials and Equipment Needed

- Steel Plates: For the frame and jaw components.

- Steel Rods: For the pivot points.

- Bolts and Nuts: For assembly.

- Electric Motor: For power.

- Pulley and Belts: To transfer power from the motor to the jaw.

- Welding Equipment: For fabricating steel parts.

- Heavy-duty Springs: To allow the jaw to move.

- Grinders, Drills, Saws: For shaping and assembling parts.

- Protective Gear: Helmets, gloves, safety glasses, and steel-toed boots.

Steps to Build a Rock Crusher

-

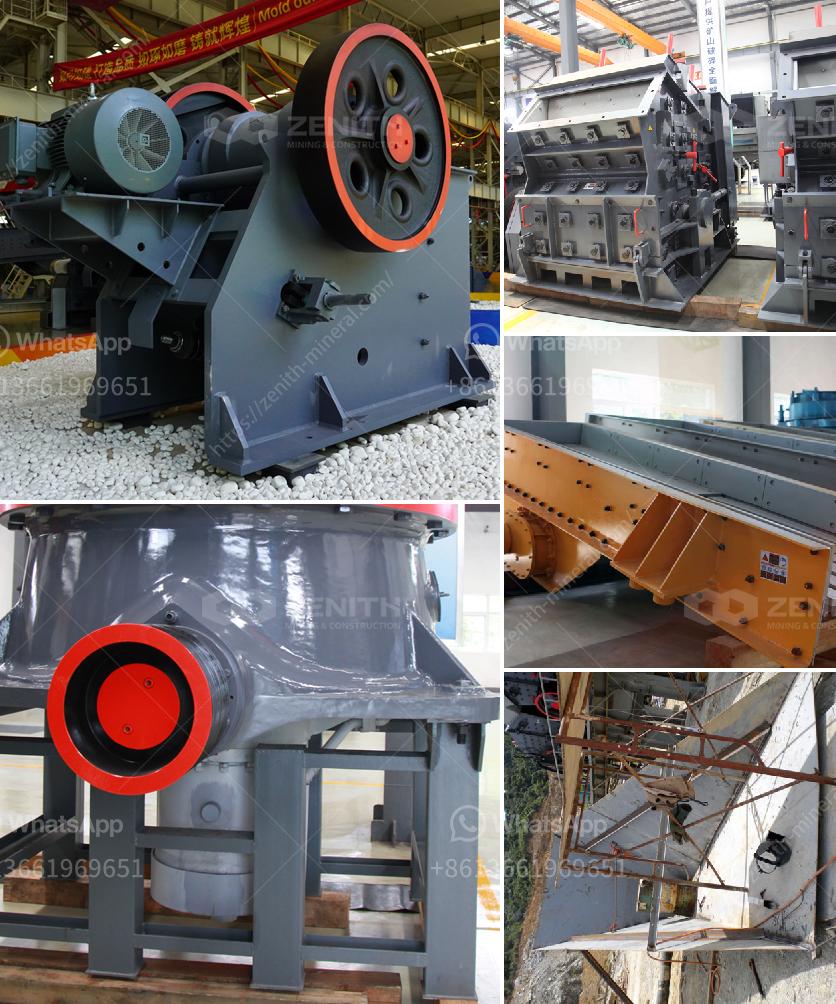

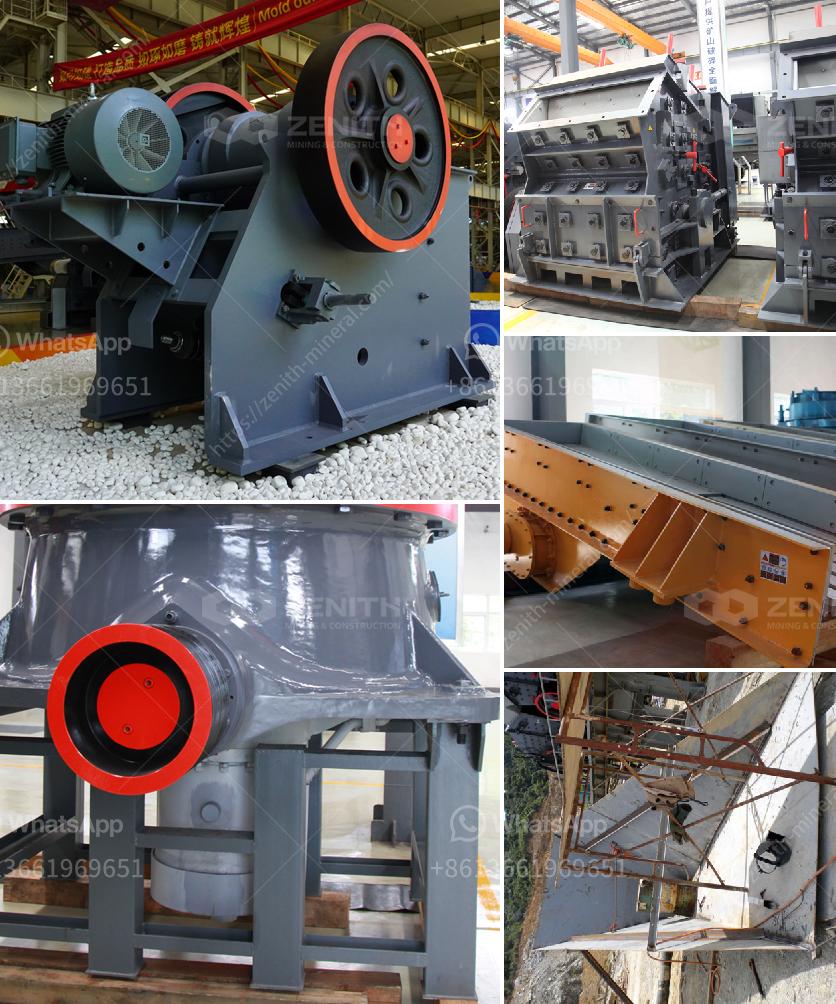

Design the Crusher:

- Sketch or draft a blueprint of the crusher you want to build.

- Decide on the dimensions and the mechanism (e.g., jaw crusher, gyratory crusher).

-

Construct the Frame:

- Cut the steel plates to size based on your design.

- Weld the plates together to form a sturdy frame.

- Ensure the frame is balanced and stable.

-

Build the Jaw Assembly:

- Cut and shape steel plates to form the jaws.

- Attach the steel rods at pivot points where the jaw will move.

- Install heavy-duty springs to ensure the jaw returns to its original position after a crush.

- Secure the jaw assembly to the frame.

-

Attach the Motor:

- Mount the electric motor onto the frame.

- Connect the pulley and belt system to transfer power to the jaw.

-

Test and Adjust:

- Double-check all bolts and welding for security.

- Test-run the crusher without any rocks to ensure everything moves properly.

- Load small rocks to test and ensure the crusher grinds them effectively.

- Make necessary adjustments to improve performance.

-

Safety Checks:

- Ensure all protective guards are in place.

- Train operators on safe usage.

- Regularly inspect the crusher for any wear and tear.

Tips

- Local Regulations: Check local regulations and get necessary permits.

- Local Materials: Source materials locally to reduce costs.

- Maintenance: Regular maintenance is crucial.

- Expert Consultation: Consider consulting with a mechanical engineer or an experienced fabricator.

Safety Precautions

- Always wear protective gear when working.

- Keep a first aid kit nearby.

- Make sure the work area is clear of obstructions.

- Ensure the equipment is powered off when making adjustments or repairs.

By following these steps and taking the necessary precautions, you can build a functional and efficient rock crusher tailored to your needs.