Calculating the wear life of blow bars in impact crushers involves several considerations:

1. Material Composition:

- Hardness and Toughness: Check the material of the blow bars. Variants include high chrome, medium chrome, or martensitic, each offering different wear characteristics.

- Feed Material: Analyze the abrasiveness and hardness of the material being processed.

2. Crusher Settings:

- Rotor Speed: Higher speeds can increase wear but also improve production.

- Gap Settings: Adjusting the gap between the rotor and the impact zone can impact wear.

3. Operational Factors:

- Feed Size: Larger feed size can increase wear on blow bars.

- Feed Rate: Consistent feed rates can reduce wear, while frequent stopping and starting can increase it.

- Maintenance: Regular inspections and timely rotation or replacement of blow bars extend wear life.

4. Empirical Data:

- Historical Data: Use historical performance data of blow bars under similar operating conditions as a baseline.

- Wear Patterns: Regular inspection of wear patterns helps in making more precise predictions.

Basic Calculation Steps:

-

Determine Average Wear Rate:

- Collect data on the mass or thickness of blow bars at regular intervals.

- Calculate the average wear rate per hour or per ton of processed material.

-

Estimate Wear Life:

- If mass (M) and feed rate (F) are known:

- *Wear Life ( L ) (hours) = M / (F Wear Rate per ton)**

- If material thickness (T) and usage rate (U) are available:

- *Wear Life ( L ) (hours) = T / (U Wear Rate per hour)**

Example:

Additional Considerations:

- Varied Feed Material: Adjust the calculations if processing different materials intermittently.

- Environmental Conditions: High humidity, dust, and temperature fluctuations can affect wear.

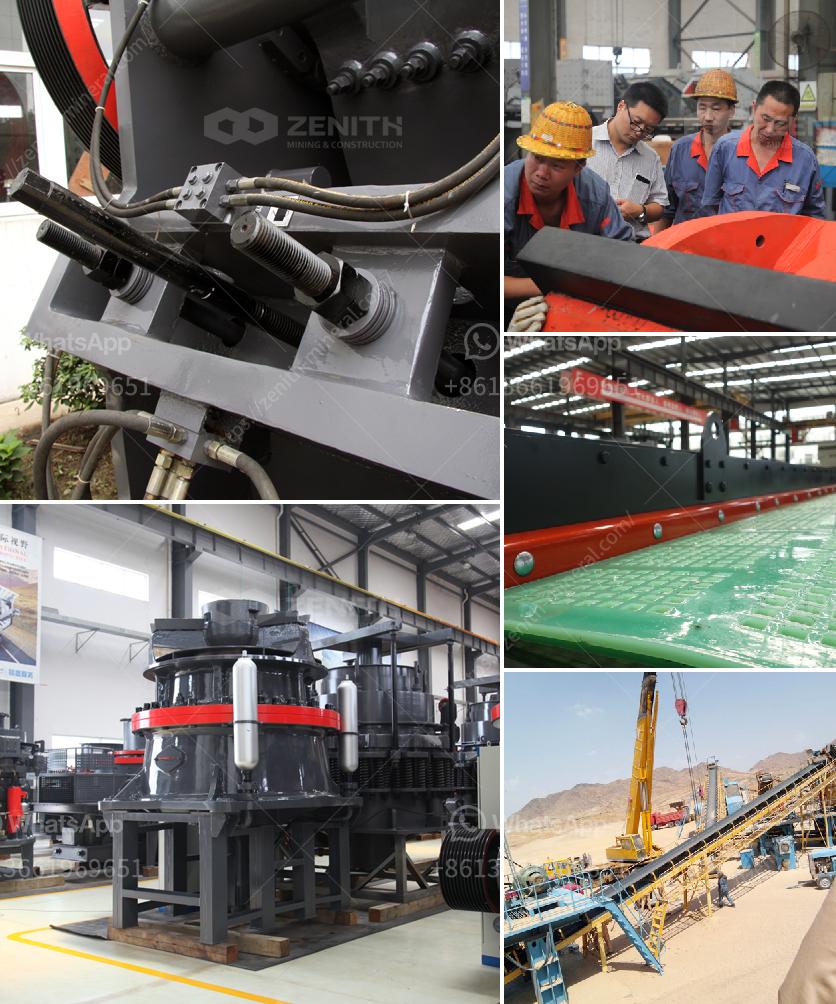

Make sure to consult with the manufacturer for more precise data and tailored formulas, as they might have proprietary wear life prediction tools based on extensive empirical data specific to their equipment.