Iron mining and refining is a complex process that involves several stages, each requiring specific techniques and equipment. Here's a detailed overview of the entire process:

Mining of Iron

-

Exploration and Prospecting:

- Geological Surveys: The first step in mining iron is to locate iron ore deposits. This is done through geological surveys and prospecting. Geologists use various methods, including satellite imagery, magnetic surveys, and drilling, to identify potential ore bodies.

- Sampling and Analysis: Once a potential deposit is found, samples are taken and analyzed to determine the quality and quantity of the ore. This helps in assessing the feasibility of mining the deposit.

-

Extraction:

- Open-Pit Mining: Most iron ore is mined using open-pit methods. This involves removing the surface vegetation, soil, and rock (overburden) to access the ore beneath. Large machinery, such as excavators and dump trucks, are used to remove the overburden and transport the ore.

- Underground Mining: In some cases, where the ore body is deep underground, underground mining methods are used. This involves creating tunnels and shafts to reach the ore. Miners use drills, explosives, and other equipment to extract the ore.

-

Blasting and Hauling:

- Blasting: Once the ore is exposed, it is often blasted to break it into smaller pieces. This is done using explosives placed in drilled holes.

- Hauling: The broken ore is then loaded onto large trucks or conveyor belts and transported to the processing plant.

Refining of Iron

-

Crushing and Grinding:

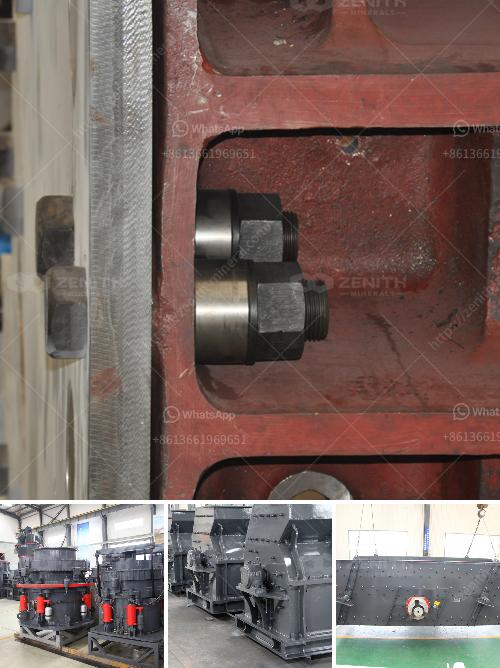

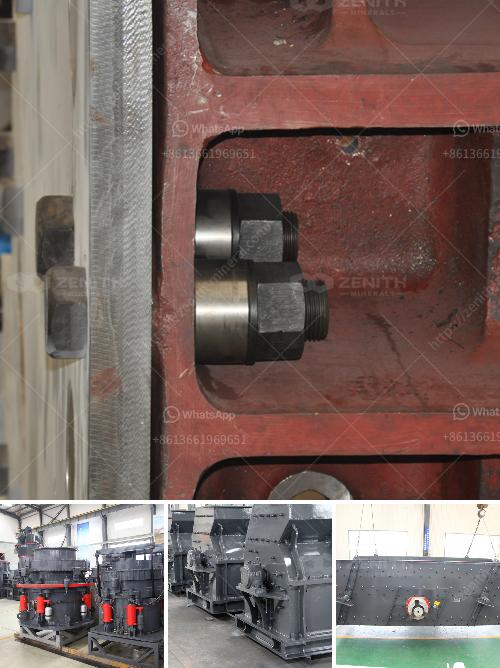

- Primary Crushing: The ore is first crushed using jaw crushers or gyratory crushers to reduce it to a manageable size.

- Secondary Crushing and Grinding: The crushed ore is then further reduced in size using cone crushers, ball mills, or rod mills. This process helps to liberate the iron particles from the surrounding rock.

-

Concentration:

- Magnetic Separation: Since iron is magnetic, magnetic separators are used to separate the iron ore from the non-magnetic waste material. This process increases the iron content of the ore.

- Flotation: In some cases, flotation methods are used to concentrate the ore. This involves adding chemicals to a slurry of ground ore and water, causing the iron particles to attach to air bubbles and float to the surface, where they can be skimmed off.

-

Pelletizing:

- Formation of Pellets: The concentrated iron ore is mixed with a binder (such as bentonite clay) and rolled into small balls or pellets. These pellets are then heated in a furnace to harden them. Pelletizing makes the ore easier to handle and improves its performance in the blast furnace.

-

Smelting:

- Blast Furnace: The iron ore pellets are then fed into a blast furnace along with coke (a form of carbon) and limestone. The blast furnace is a large, cylindrical structure that operates at high temperatures. Hot air is blown into the furnace, causing the coke to burn and produce carbon monoxide, which reacts with the iron ore to produce molten iron and carbon dioxide.

- Formation of Slag: The limestone acts as a flux, helping to remove impurities from the iron ore. These impurities form a slag, which floats on top of the molten iron and can be removed.

-

Refining:

- Basic Oxygen Furnace (BOF): The molten iron from the blast furnace is transferred to a basic oxygen furnace, where it is further refined. Oxygen is blown into the molten iron, causing impurities such as carbon, silicon, and phosphorus to oxidize and form slag. The slag is removed, leaving behind purified molten iron.

- Electric Arc Furnace (EAF): In some cases, an electric arc furnace is used for refining. This method uses electrical energy to melt scrap steel and iron, which is then refined to produce high-quality steel.

-

Casting and Forming:

- Continuous Casting: The refined molten iron is poured into molds to form ingots, slabs, or billets. These are then cooled and solidified.

- Rolling and Shaping: The solidified iron is further processed in rolling mills to produce various shapes and sizes, such as sheets, bars, and rods.

Environmental and Safety Considerations

- Environmental Impact: Iron mining and refining can have significant environmental impacts, including habitat destruction, water pollution, and air pollution. Companies are required to follow environmental regulations and implement measures to minimize these impacts, such as land reclamation, water treatment, and emission controls.

- Safety: Mining and refining operations can be hazardous, with risks such as cave-ins, explosions, and exposure to toxic substances. Strict safety protocols and protective equipment are essential to ensure the safety of workers.

In summary, the process of mining and refining iron involves several stages, from exploration and extraction to concentration, smelting, and refining. Each stage requires specialized techniques and equipment, and there are important environmental and safety considerations to address.