The cost of a mobile crushing and screening plant can vary significantly based on several factors. Here are some of the key considerations that can influence the price:

Capacity: The production capacity of the plant is one of the primary factors affecting the cost. Plants with higher capacity can process more material per hour, which typically makes them more expensive. For example, a plant with a capacity of 200 tons per hour will generally cost more than one with a capacity of 100 tons per hour.

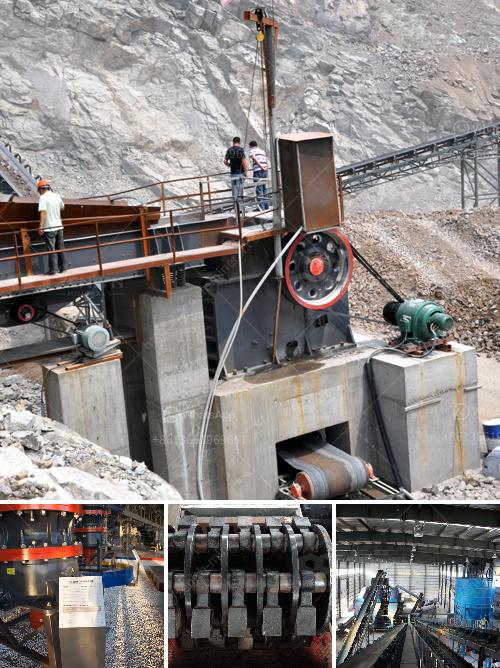

Type of Equipment: The specific types of crushers and screens included in the plant can also impact the cost. Different types of crushers (e.g., jaw crushers, cone crushers, impact crushers) and screens (e.g., vibrating screens, trommel screens) have different price points. The choice of equipment depends on the material being processed and the desired end product.

Brand and Manufacturer: The brand and manufacturer of the equipment can significantly influence the price. Well-known and reputable brands often come with a higher price tag due to their reliability, durability, and after-sales support. However, they may offer better long-term value due to lower maintenance costs and higher efficiency.

Mobility and Configuration: Mobile plants are designed to be easily transported and set up at different locations. The level of mobility and the complexity of the configuration (e.g., single or multiple trailers, integrated or modular design) can affect the cost. More advanced and flexible configurations tend to be more expensive.

Additional Features: Additional features and options, such as automation systems, dust suppression systems, and advanced control panels, can add to the overall cost. These features can enhance the efficiency and safety of the plant but come at an additional expense.

Geographical Location: The cost can also vary based on the geographical location due to differences in shipping, import duties, and local market conditions. Plants manufactured in certain regions may be cheaper due to lower labor and production costs.

New vs. Used: Purchasing a new plant will generally be more expensive than buying a used one. However, used plants may come with higher maintenance costs and shorter lifespans.

Given these factors, the cost of a mobile crushing and screening plant can range from around $100,000 to over $1,000,000. For a more precise estimate, it is advisable to contact manufacturers or suppliers directly, providing them with specific details about your requirements and the material you intend to process. They can offer tailored quotes based on your needs.