For concrete crushing, several types of machinery are commonly used to break down concrete into smaller, more manageable pieces. Here are some of the key machines required:

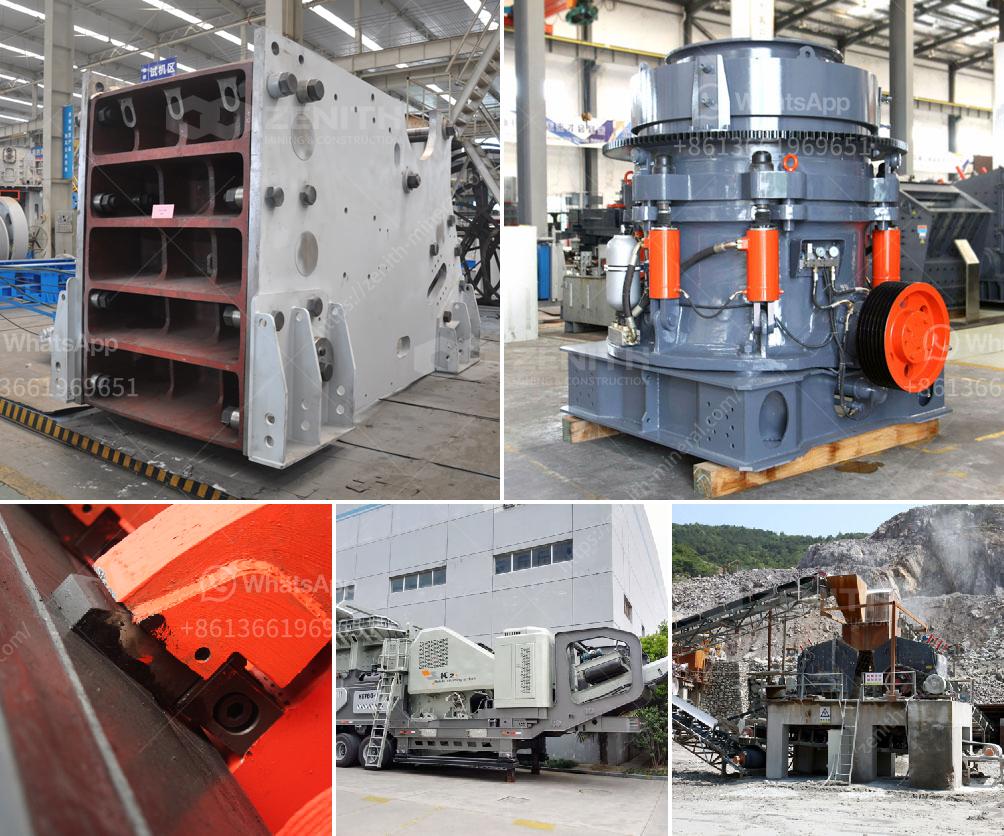

Jaw Crushers: These machines are typically used as primary crushers and are designed to reduce large pieces of concrete into smaller, more manageable sizes for further processing.

Impact Crushers: Impact crushers are often used as secondary crushers. They use high-speed impact to break down concrete materials, producing a more cubical product which is often preferred for some construction applications.

Cone Crushers: These are used in secondary or tertiary crushing stages and can handle various types of material, including concrete. They are known for producing a high-quality, uniform product.

Portable Crushers: These mobile units can be moved to different sites and are useful for on-site concrete crushing. They combine feeding, crushing, and screening into one machine, which simplifies the process and reduces the need for multiple pieces of equipment.

Screening Plants: After the concrete is crushed, it often needs to be separated into different size fractions. Screening plants help in classifying the crushed materials into various sizes for different applications.

Recycling Systems: These systems typically include various conveyors and separation technologies to sort and process the crushed concrete, removing any contaminants such as rebar or dirt.

Excavators with Hydraulic Concrete Crushers: These are attachments that can be added to excavators, allowing them to crush and process concrete on-site. They are excellent for demolition and recycling applications as they can handle larger volumes of material.

Depending on the specific requirements and the scale of the project, the selection of equipment may vary, but these are the primary types of machinery used in concrete crushing operations.