Mining underground copper ore involves several key steps, ensuring safety and efficiency. Here’s a simplified overview of the process:

-

Exploration and Surveying:

- Conduct geological surveys to locate underground copper deposits.

- Use advanced tools like satellite imagery, seismic measurements, and drilling samples to map the ore body.

-

Mine Design and Planning:

- Design the mine layout, including access tunnels, haulage routes, and ventilation systems.

- Develop a detailed mine plan ensuring the stability of underground structures and considering the ore grade and distribution.

-

Site Preparation:

- Set up surface infrastructure, including offices, maintenance shops, and processing facilities.

- Clear the area and establish access roads if necessary.

-

Excavation:

- Construct access tunnels to reach the ore body. This can involve vertical shafts, inclined ramps, or horizontal drifts.

- Ensure proper ventilation, lighting, and drainage systems are in place.

-

Drilling and Blasting:

- Drill holes into the ore body for blasting.

- Carefully plan and execute blasting operations to fragment the ore while maintaining overall structural integrity.

-

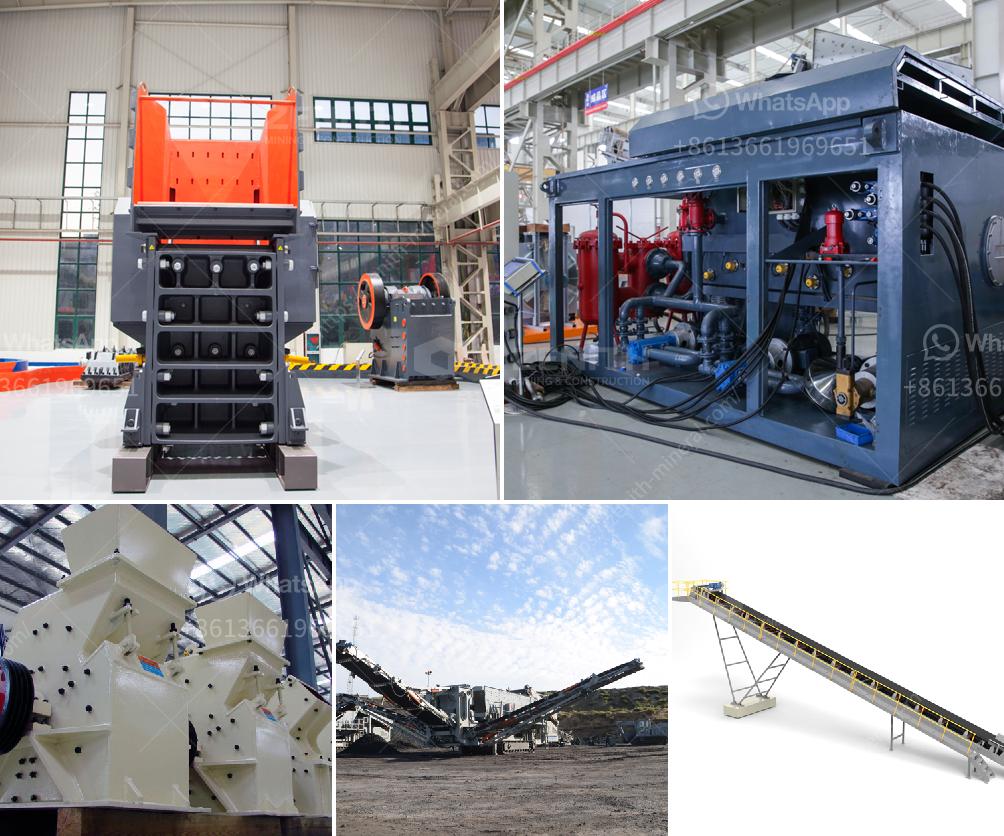

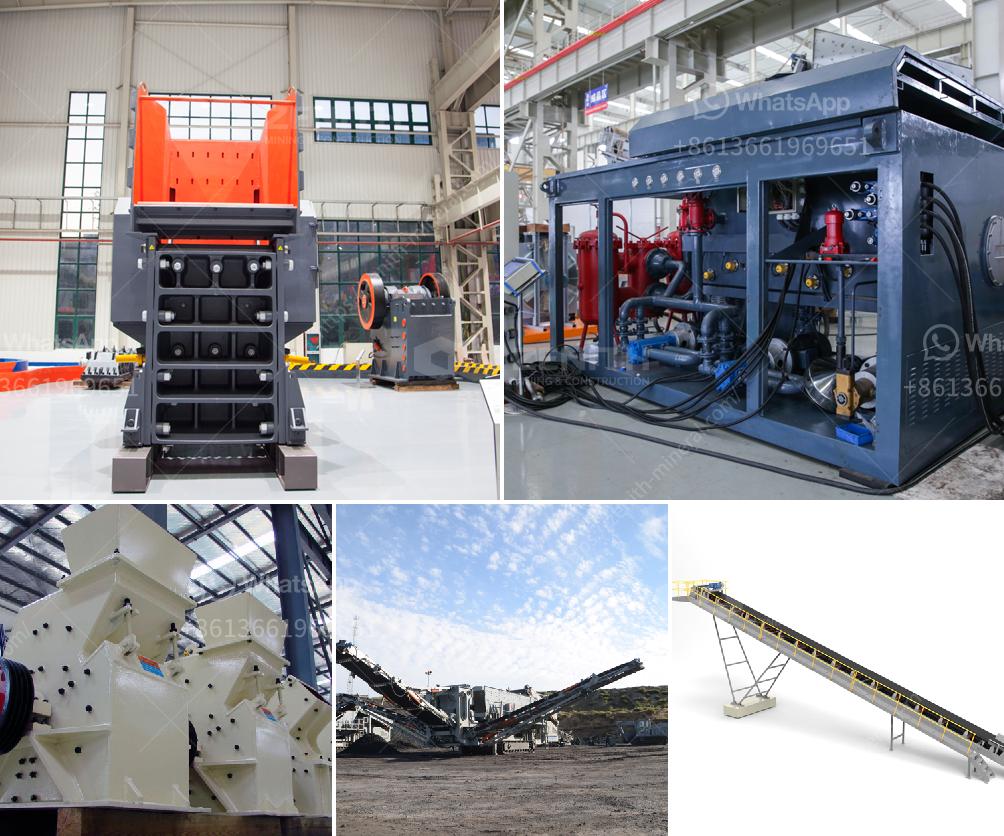

Ore Extraction:

- Use machinery like loaders, trucks, and conveyors to transport the broken ore from the blast site to the surface.

- Employ methods such as cut-and-fill, room-and-pillar, or block caving depending on the ore body and surrounding geology.

-

Processing:

- Crush and grind the extracted ore to liberate copper minerals.

- Use flotation to concentrate the copper, separating it from the surrounding minerals.

- Additional refining steps may follow to produce pure copper.

-

Rehabilitation and Closure:

- Once mining is complete, rehabilitate the site by filling in tunnels, replanting vegetation, and ensuring environmental compliance.

- Monitor the site for any long-term environmental impacts.

-

Safety Measures:

- Continuously monitor air quality, ground stability, and machinery conditions.

- Train workers on safety protocols and emergency procedures.

- Ensure proper personal protective equipment (PPE) is used at all times.

Each step requires meticulous planning and adherence to regulations to minimize environmental impact and ensure the safety of workers and surrounding communities.